Since starting my web-site over two years ago I have received many phone calls and emails from all over the country. The most asked question I get is, “where can I buy that “Dixie” lock you have on your web-site?”

To review, the “Dixie” lock was invented by a man named Sid, who owned the Dixie Lock Company in Miami. The lock is often called the “Sid” lock also. “Dixie” is now the trade name for this lock, I don’t believe the Dixie Lock Company is in business anymore. The lock I sell now is made by a company called Sentry, and the lock is called the “Sentry Door Lock Guard.”

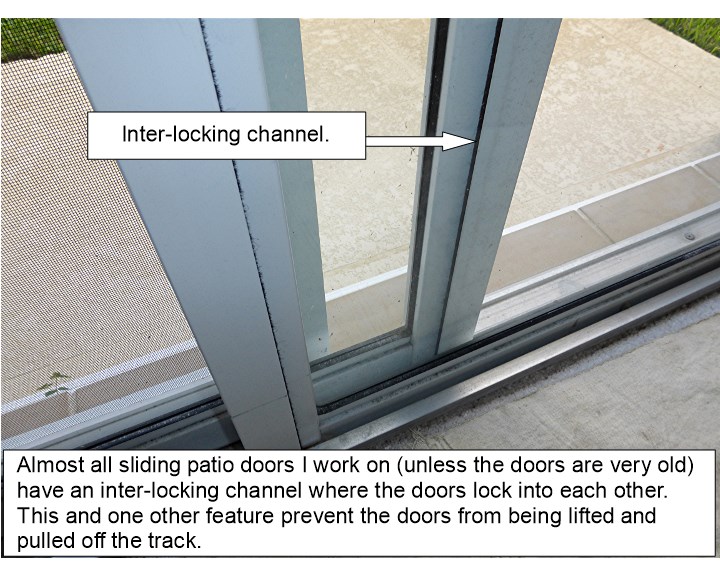

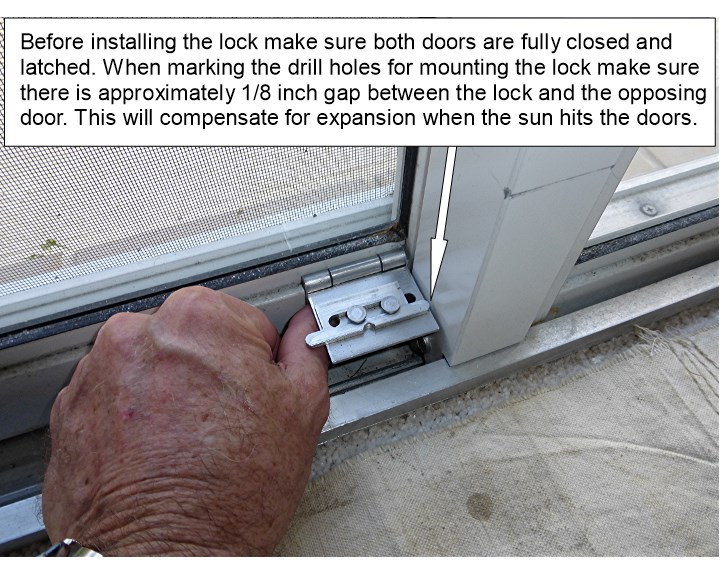

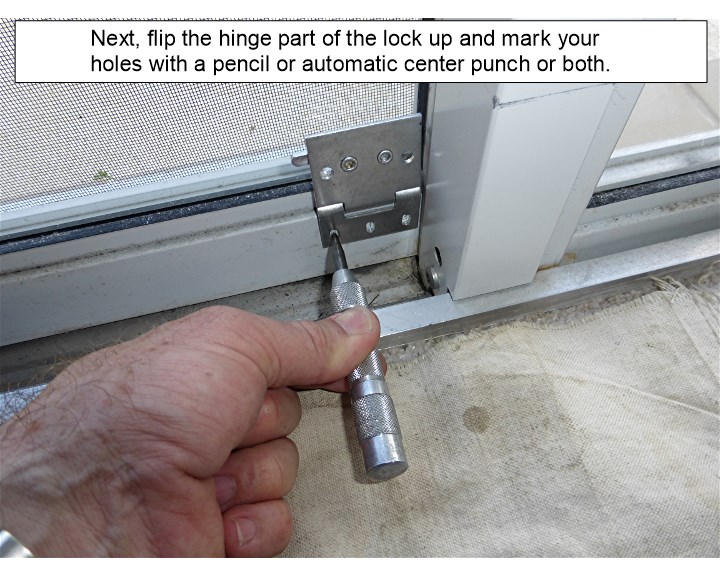

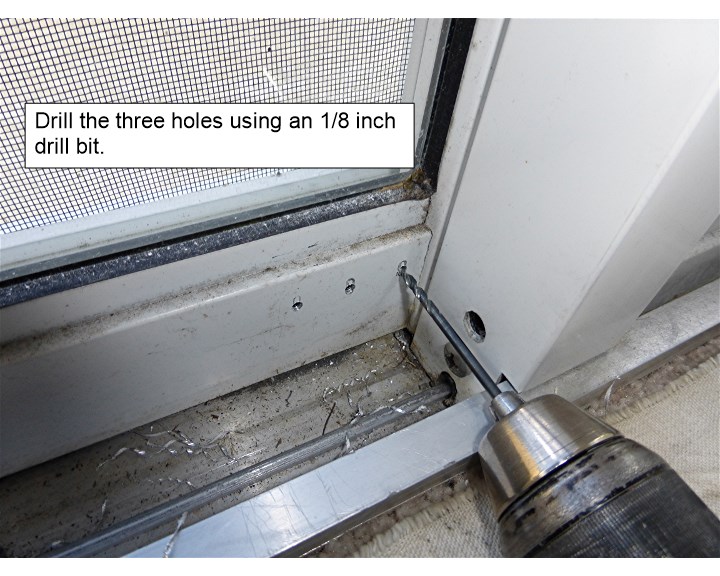

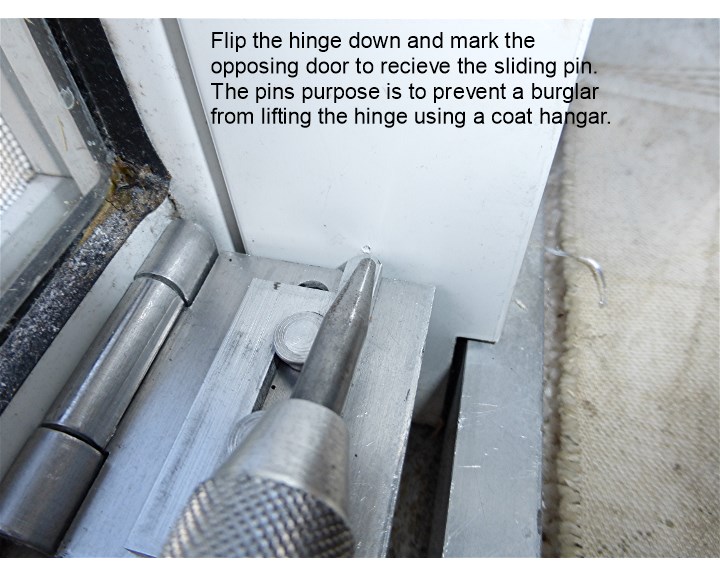

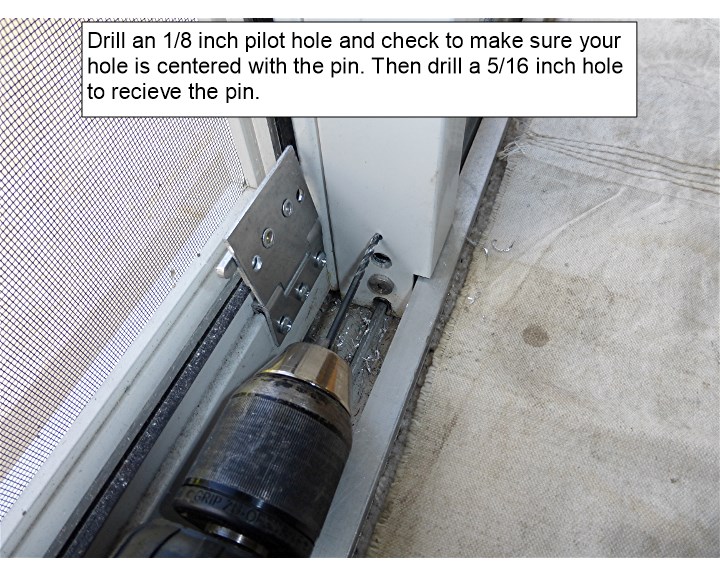

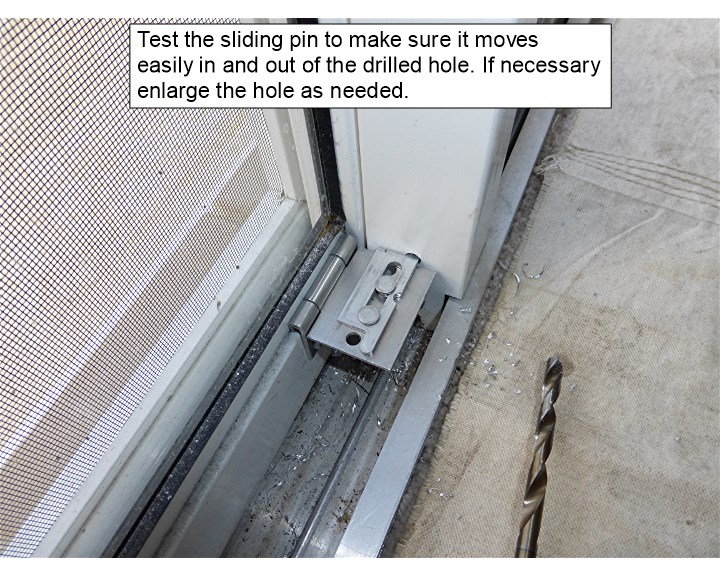

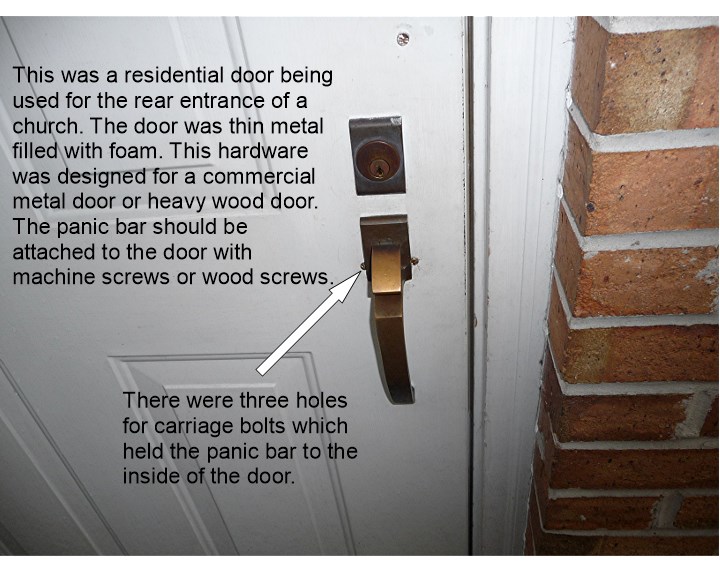

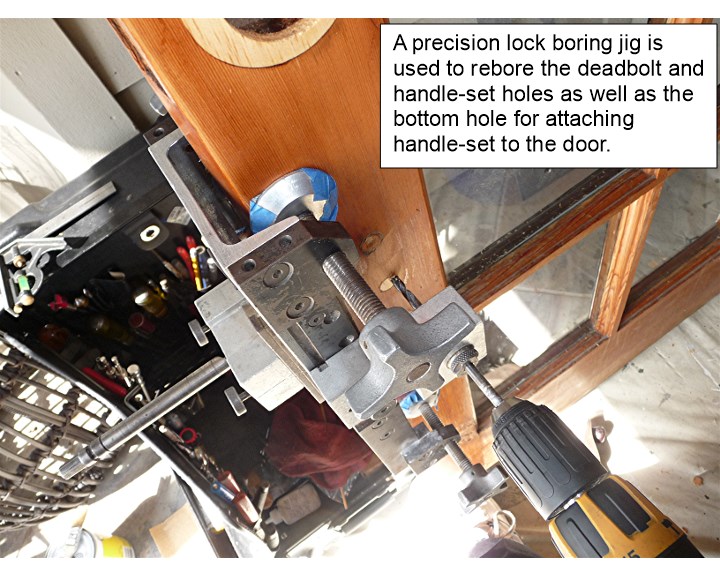

Usually this lock is only sold through your local locksmiths. You will not find this sliding patio lock in the big box stores. Also the Sentry Door Lock Guard will not come with installation instructions. The lock is intended to be installed by the locksmith or security professional. The greatest risk for the novice installer, although it is small, is breaking the glass. This could ruin your day. It is best to hire a competent locksmith with plenty of practice to install any lock.

In New Jersey where I started my locksmith career, sliding patio doors were not built to the greatest standards. Many doors could be lifted out of the track and removed, even though the door was locked. The biggest advantage to those older doors was only one door slid open, the other door was anchored in place. These doors could be locked with a broom stick or dowel cut to length and dropped in the track. We installed many other locks designed for patio doors, but never the “Dixie” lock.

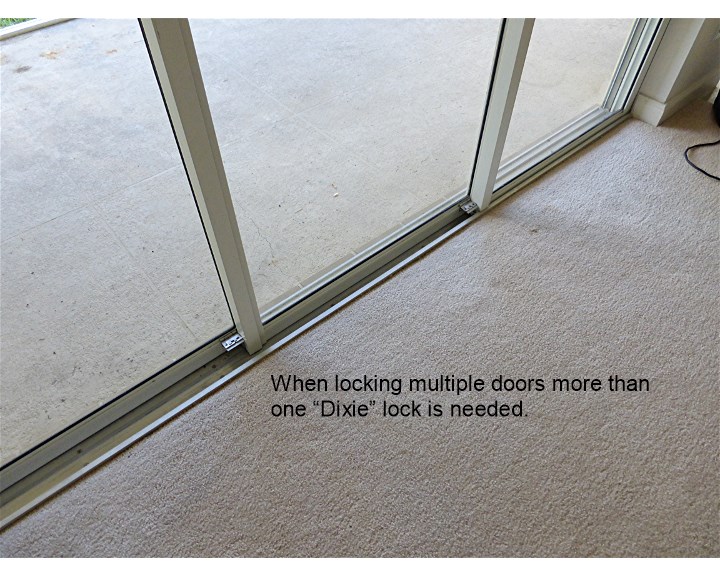

When I started working in Florida I was introduced to the “Dixie” lock. In south Florida most sliding patio doors bypass each other. In others words, both doors move. Dropping a stick in the track will only lock one sliding door. The best way to lock these doors is to lock one door against the other. The “Dixie” lock did this more simply and effective than anything on the market, and it still does.

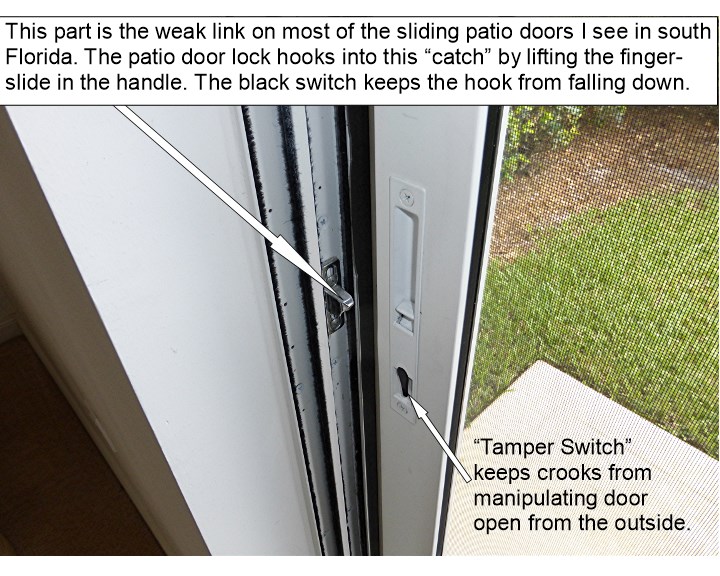

Sliding patio doors in south Florida were made better than doors in New Jersey. The doors in Florida had an inter-locking channel which locked the outside door to the inside door when the doors were fully closed. This inter-locking channel also created a better weather seal. Also, each door locked into a weather resistant groove which does a good job of keeping the elements out and the air-conditioning in.

You might be thinking a concrete block could be thrown through the glass and all the locks by-passed. This is true, by in my 37 years I have only seen this done twice. There are products available that install like window tint to deter the large rock or sledge hammer attack. I believe the sliding door is so easy to pry open that breaking the glass is not necessary in most cases.

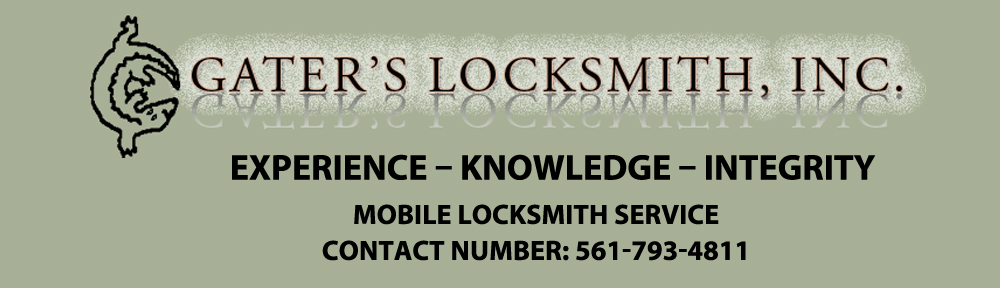

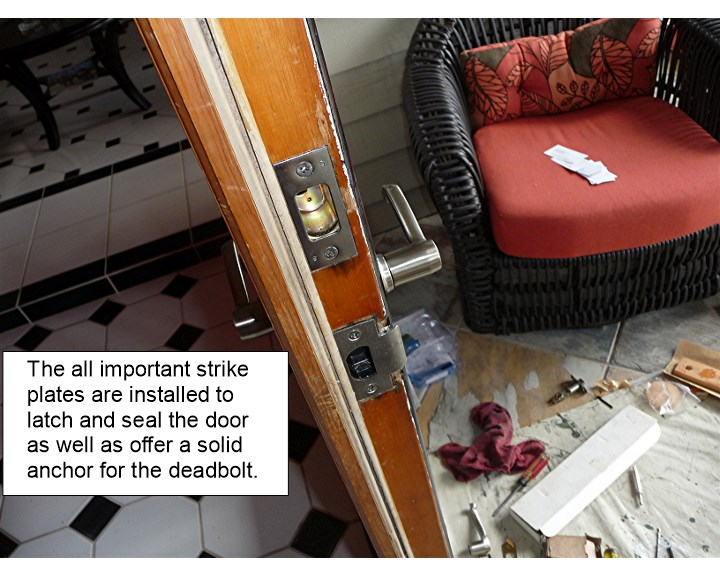

The security problem with sliding patio doors in Florida is the “catch.” The “catch” is the piece the door lock hooks into. This major piece of the doors security is made of cast pot-metal. Under the stress of a burglars crowbar or big screwdriver the “catch” will break apart. The door slides open and the bad guys go on their rampage of dumping every drawer and tearing apart every bed looking for hiding places of cash and jewelry. If there is an alarm, the crooks are gone way before any police can respond. Alarms are good, but the lock is your first line of defense against burglars, vandals and home invasions.

Remember, this lock can be purchased from and installed by your local locksmith. To find a locksmith in your area visit: www.findalocksmith.com