by Jeff Gater, CML

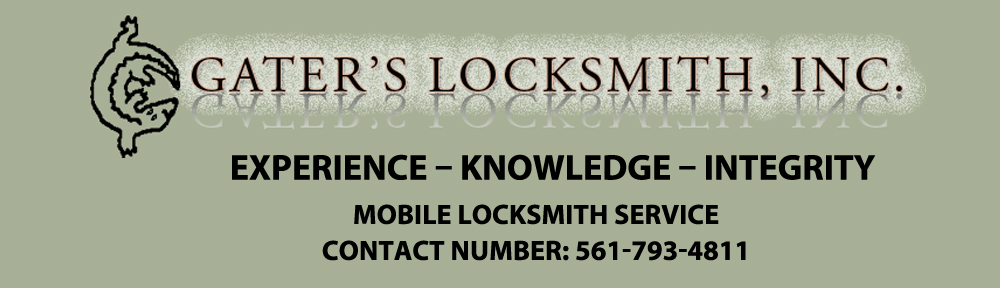

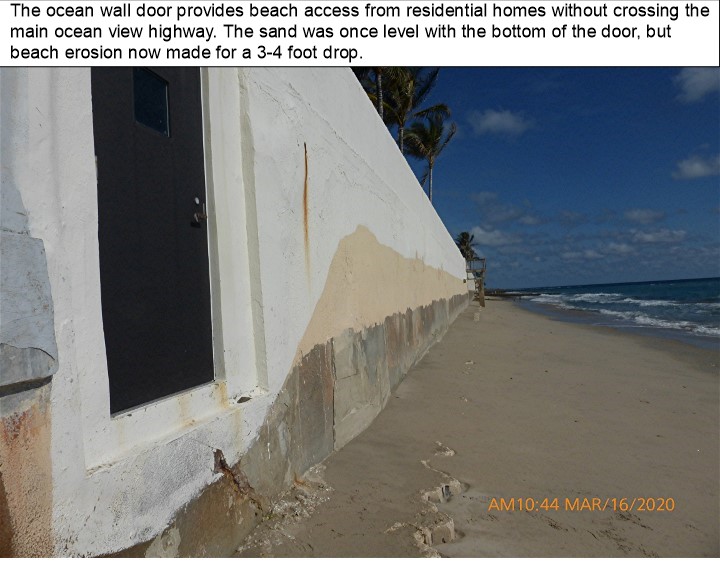

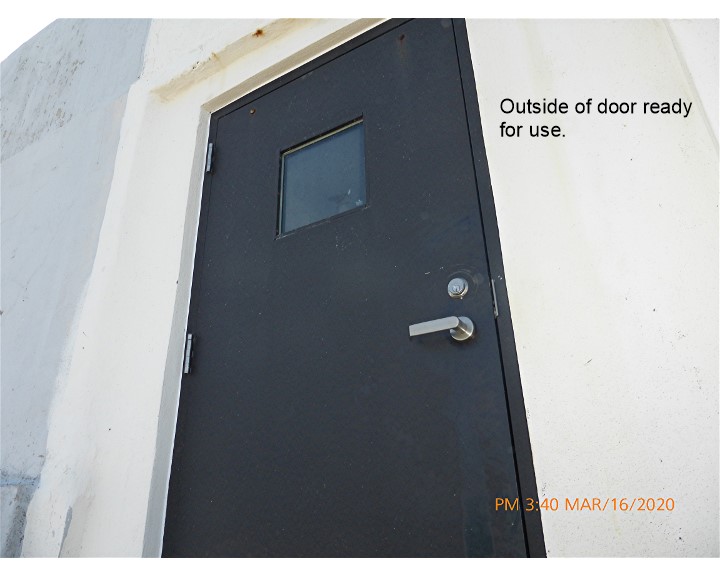

This was one of the most unusual jobs I have ever been called to do. Along a specific piece of coastline on the Atlantic Ocean there is a huge wall built along certain sections of the main boulevard to keep the waves from washing away the road. Many of the homes that are not right on the beach were built just across the street from the beach. In order to give safer access to the beach some of these homes share a tunnel which passes under the street to a door which opens up on the shoreline.

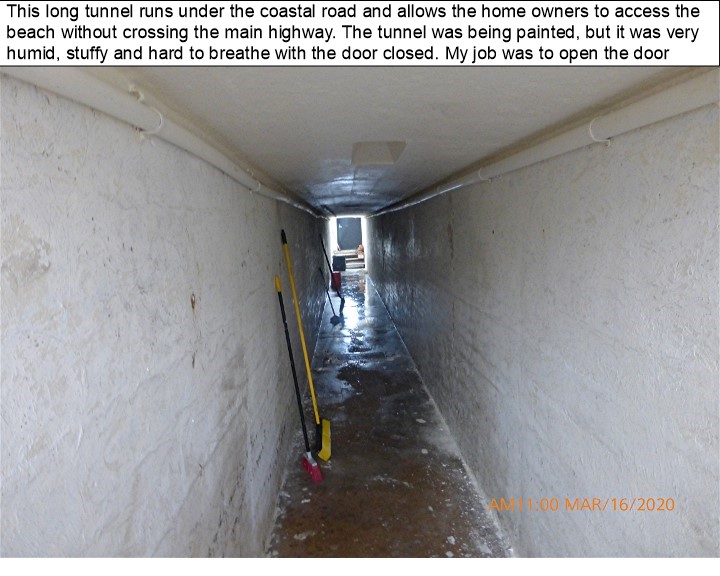

My job on this particular day was to open a stuck door in the ocean wall and replace the lock and the hinges. When I entered the tunnel there were men preparing the walls for painting. The air was heavy and it was hard to breathe. It was also very hot and humid, opening the door was more about creating a safer work environment for the painters than granting safe passage to the beach.

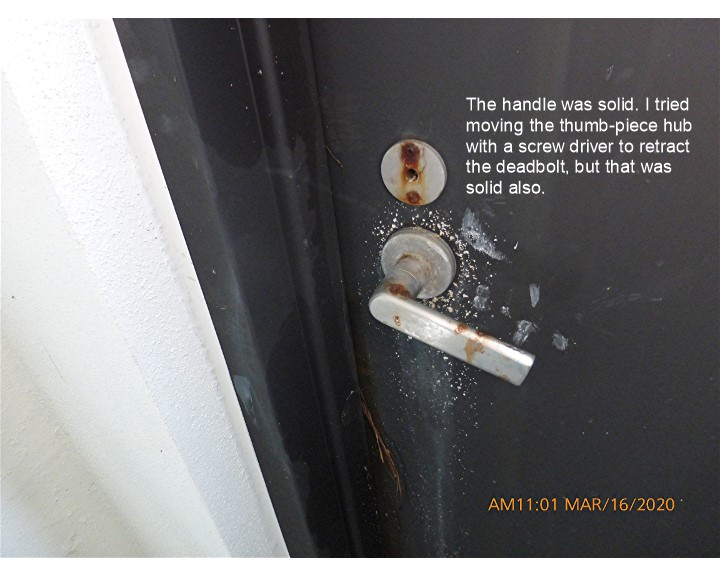

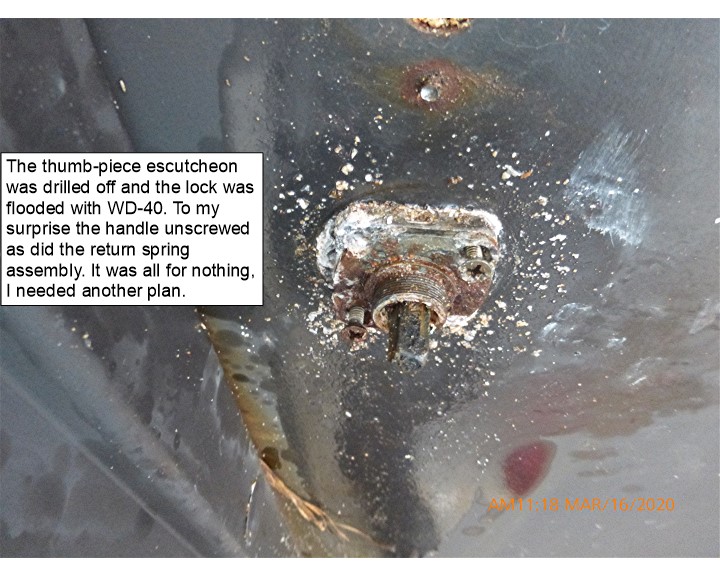

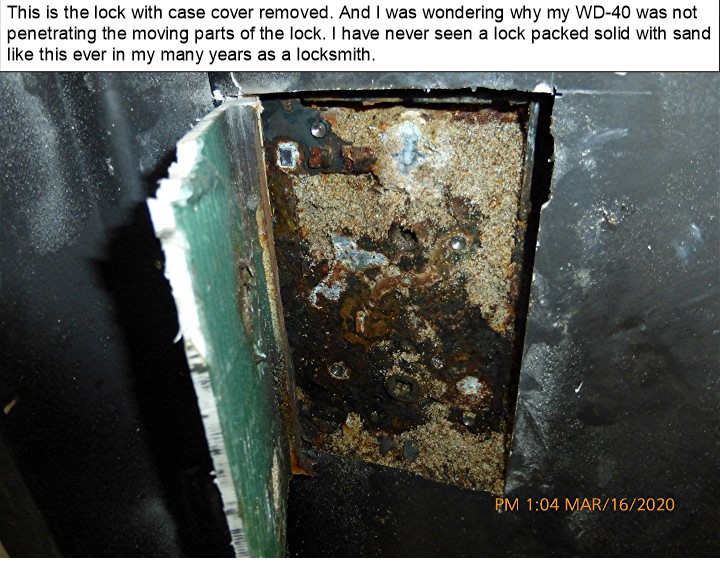

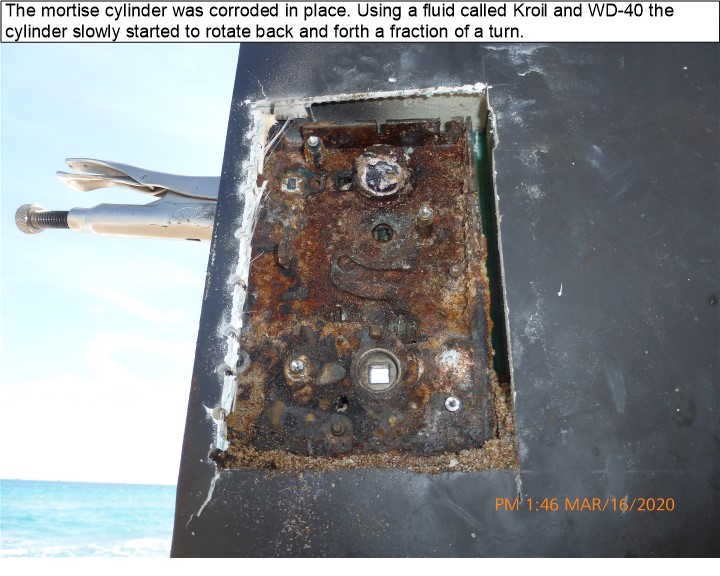

I knew the lock would have plenty of corrosion to deal with. To my surprise the inside handle unscrewed without a lot of difficulty. Under the lever rosette were two additional screws which held on the lever return spring assembly, these screws also backed out rather easy and I thought this job was going to be much easier than anticipated. But my original gut feeling was correct. After removing the parts I could with little difficulty the whole job stalled. I flooded the lock as best I could with WD-40 which works great for loosening corroded parts, but the hub which turns to retract the latch and the smaller hub used for unlocking the deadbolt were fixed solid. There was no movement in either direction.

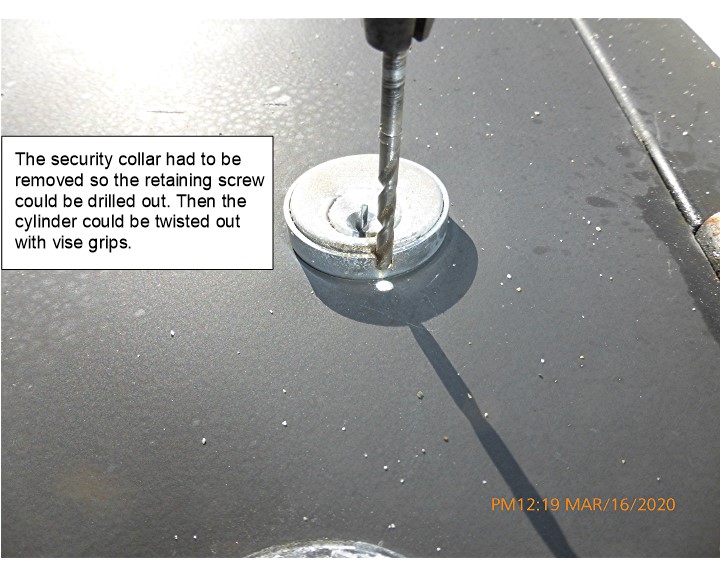

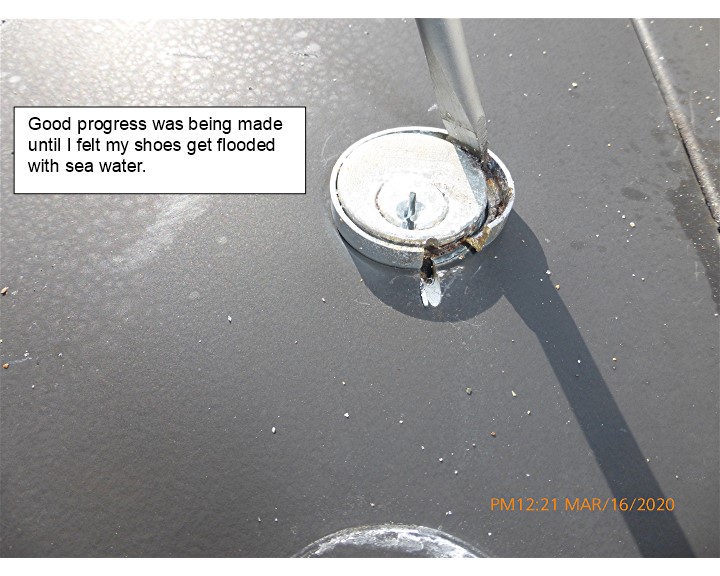

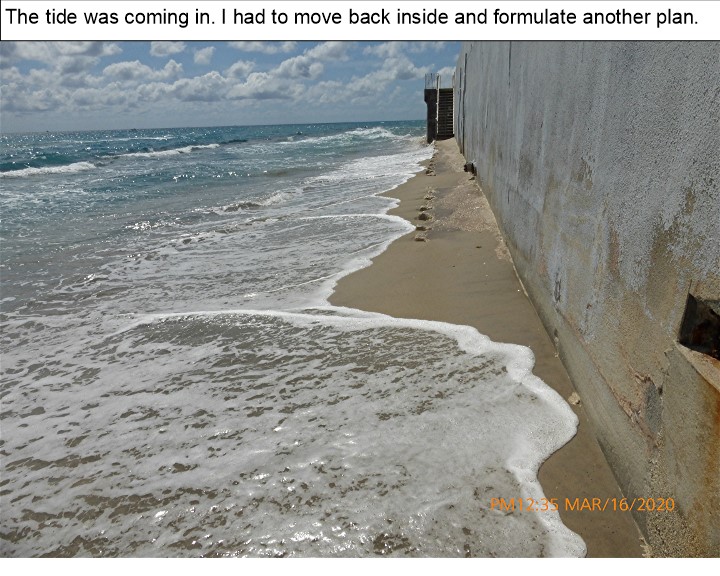

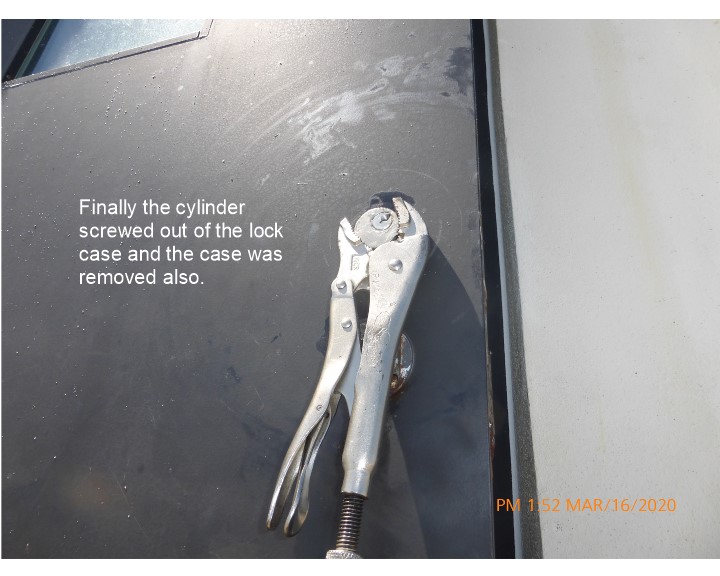

I took some tools and moved to the outside of the door along the ocean. My plan was to remove the key cylinder and retract the deadbolt with a screw driver. Just about the time I was ready to remove the mortise cylinder my feet were flooded with sea water. The tide was coming in and there was no place for me to work and avoid the incoming waves. I aborted that plan and returned to the tunnel.

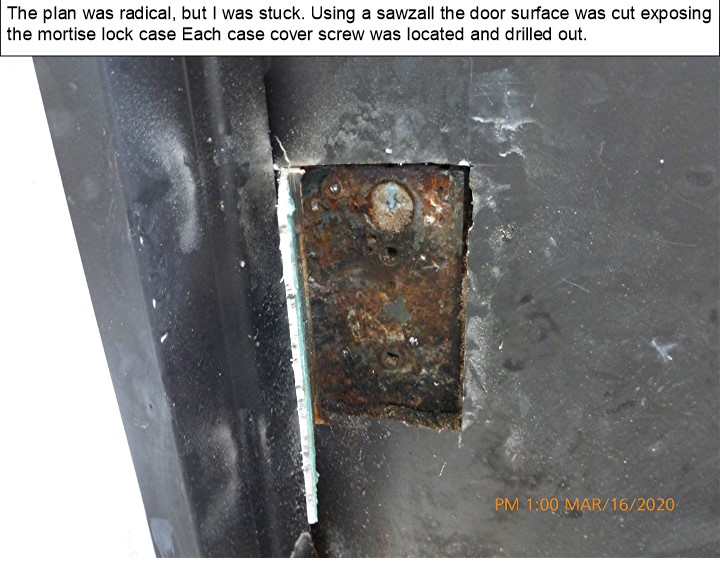

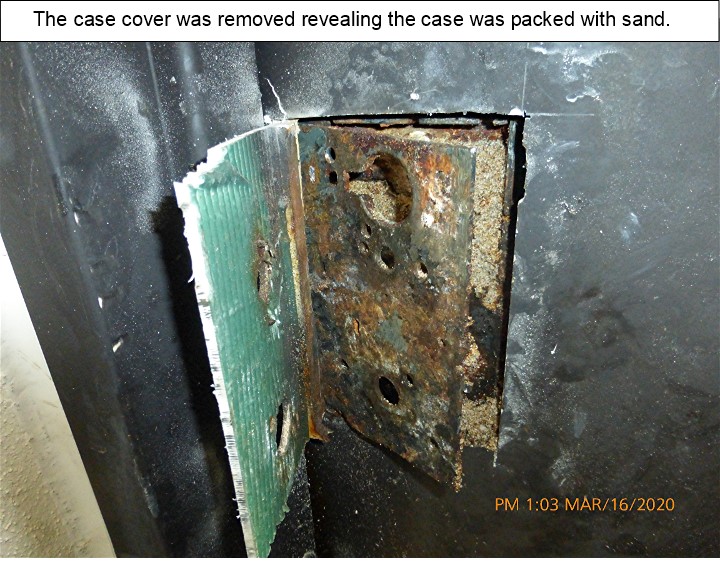

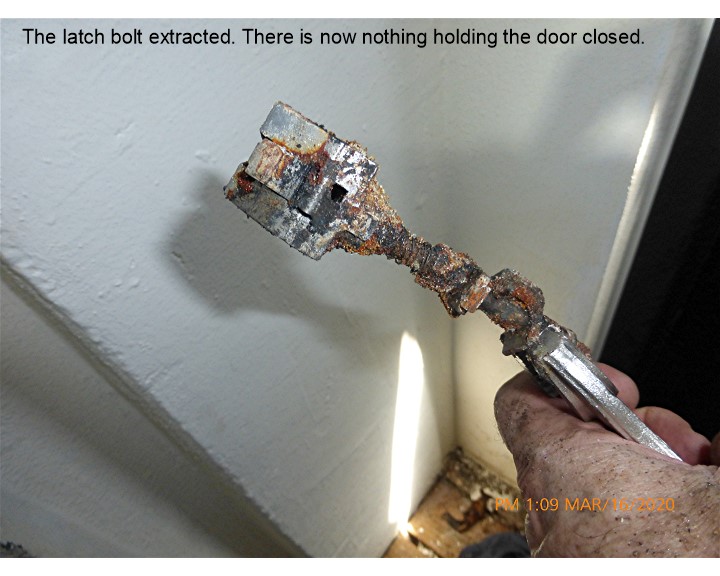

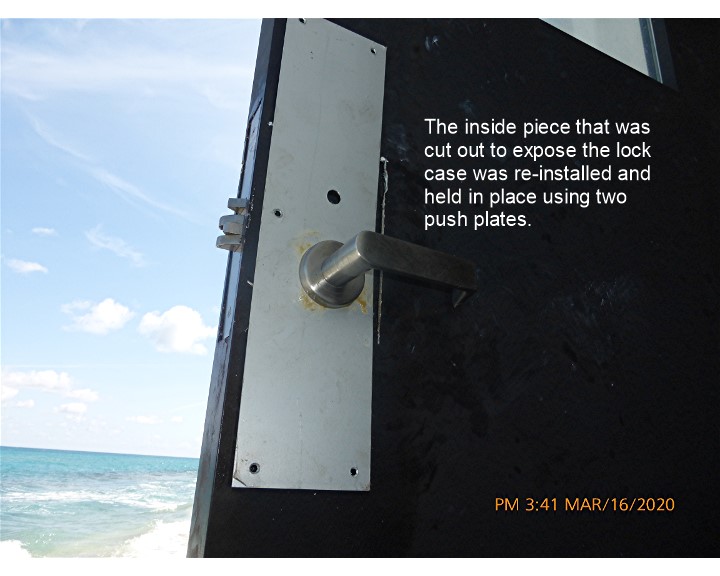

I had to get to the lock case somehow. The only way possible was to cut half way through the hollow door and expose the lock case. From there I drilled out the case screws and pulled open the case cover about an inch. I discovered the entire mortise case was packed with sand! The lock bolt and latch had no room to move even if there was no corrosion. The case cover was removed and all the sand that could be dug out with a screwdriver was removed. The lock bolt was welded to the case by corrosion and it took a hammer and cold chisel to break it loose. The latch was removed the same way and finally I was able to push the door open. The ocean breeze rushed through the tunnel and the heat and stuffiness vanished immediately.

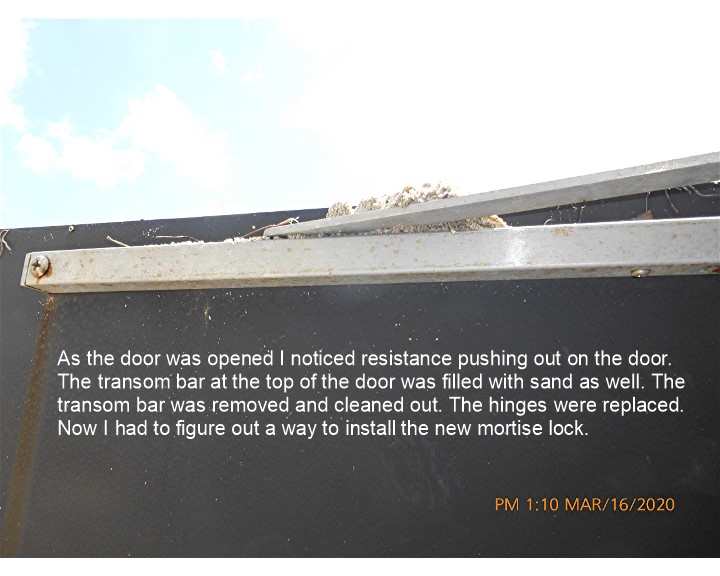

The door was resistant to push open all the way. At the top of the door was a piece of hardware called a transom bar. The purpose of this bar was to keep the door from opening beyond 90 degrees. It also contained a large spring that served as a shock absorber in case the wind whipped the door open.

The transom bar was filled with sand as well. I’m sure over the years and the couple of hurricanes that came close to this area the waves would have been breaking at the top of the wall, which in turn carried sand into every crack and crevice along the walls surface. Hence, the lock case filled with sand.

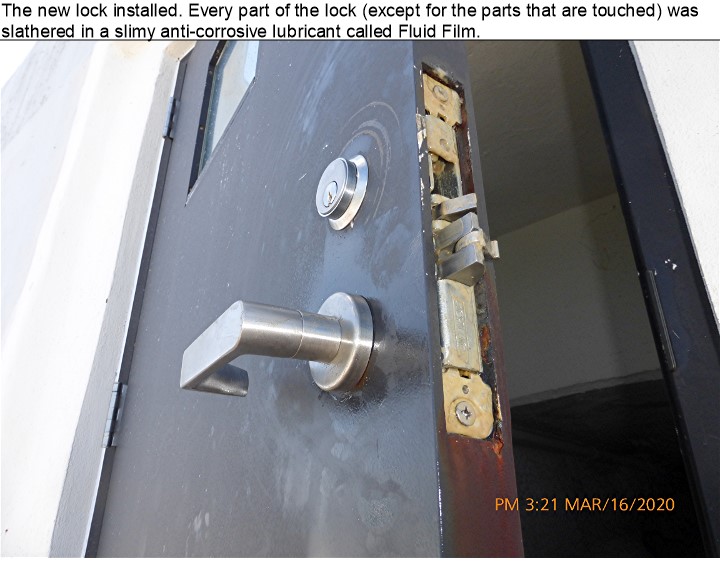

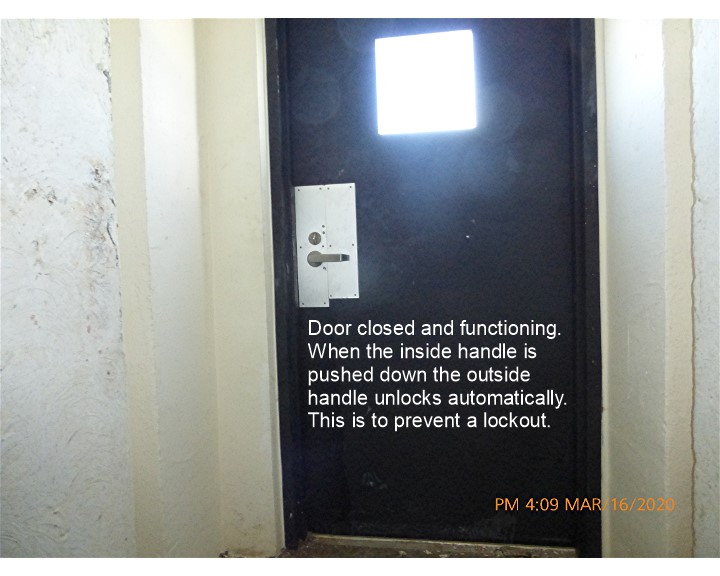

The transom bar had very little corrosion and worked perfectly after the sand was removed. The hinges were also replaced and a new lock was installed. The lock function chosen was a Schlage L9456, Corridor Lock. This function prevents an accidental lockout. When the inside lever is used to exit the tunnel the outside lever unlocks automatically. The outside lever can only be locked when the outside key or inside thumb-turn is used to throw the deadbolt. This function would allow people to visit the beach and not worry about carrying a key with them.

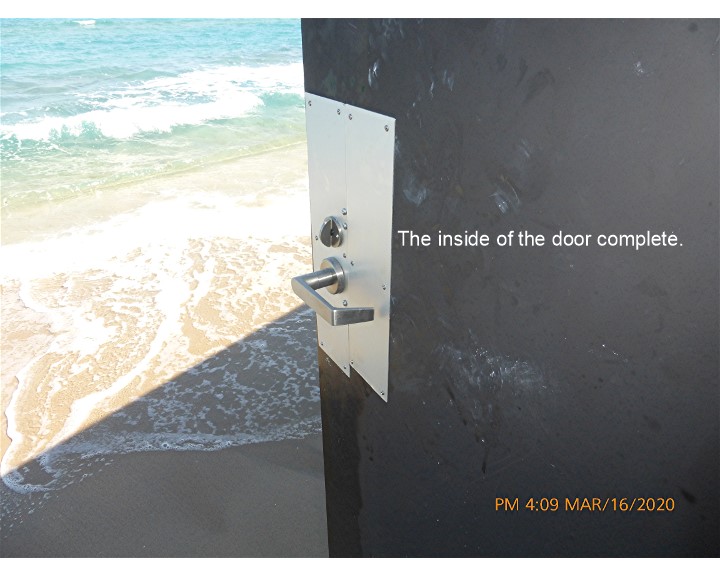

Since a section of the door was cut out, push plates were used to hold the “cut out” piece in place and give a mounting surface for the inside lever and thumb-turn. The whole job took about 6 hours to complete.