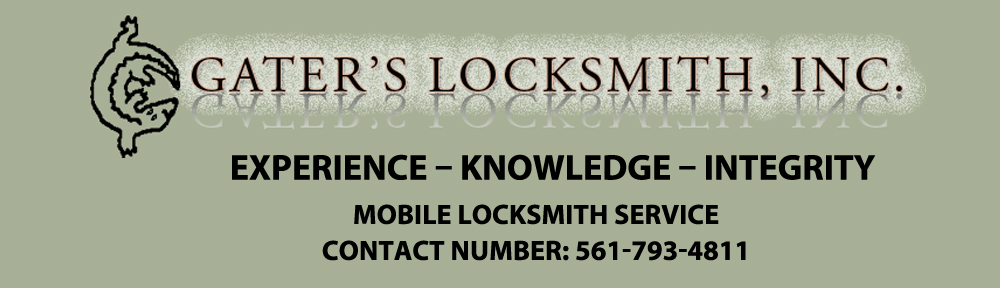

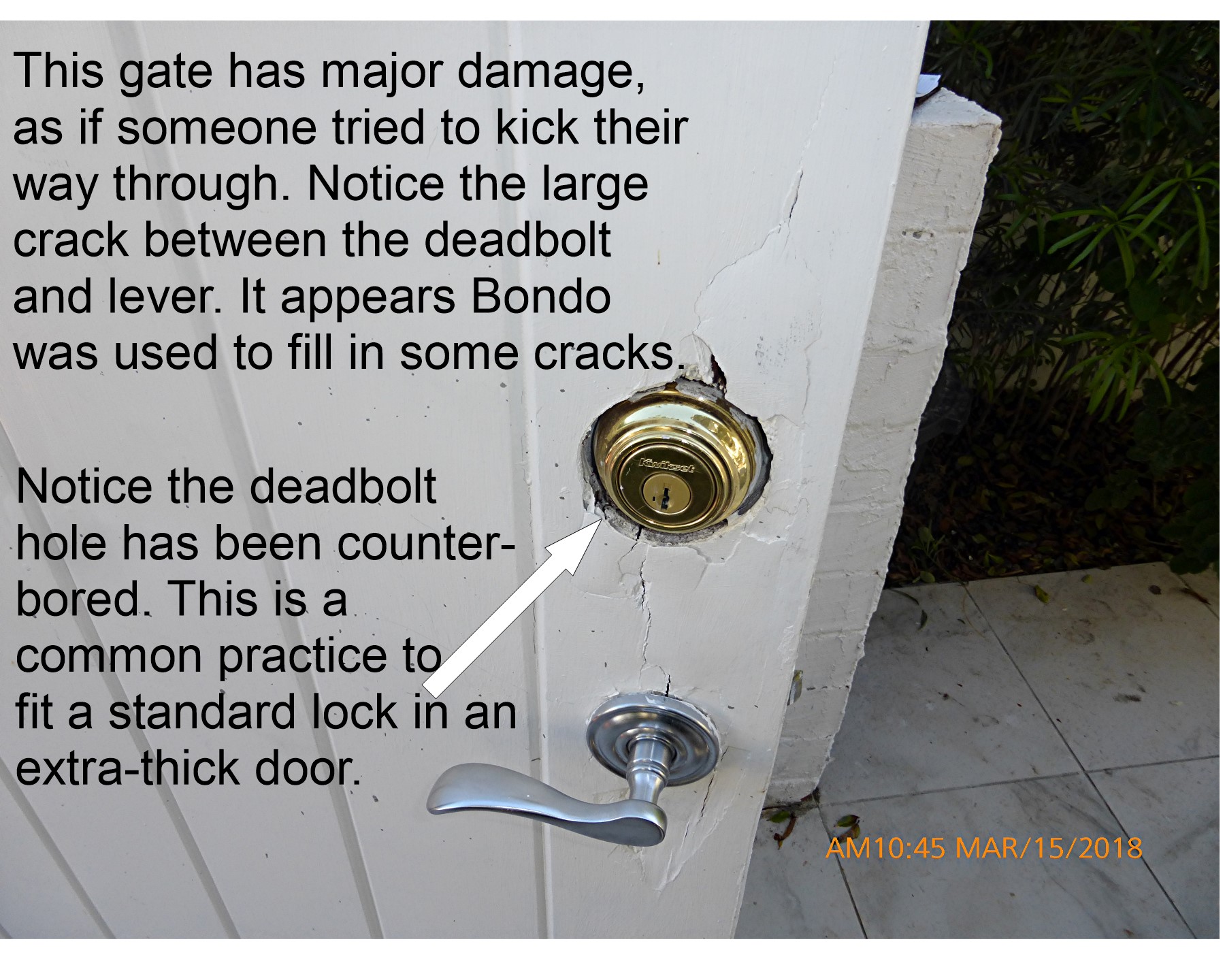

There are times when the need for new locks is obvious, but the door, or gate in this case is so badly deteriorated new locks cannot be installed until repairs are made. The gate on this job-site was 2 5/16 inches thick, about 5 feet high and 5 feet wide. Replacing the gate was ruled out because of cost. The area to be repaired was very large which made plugging, or installing new wood to re-bore impractical.

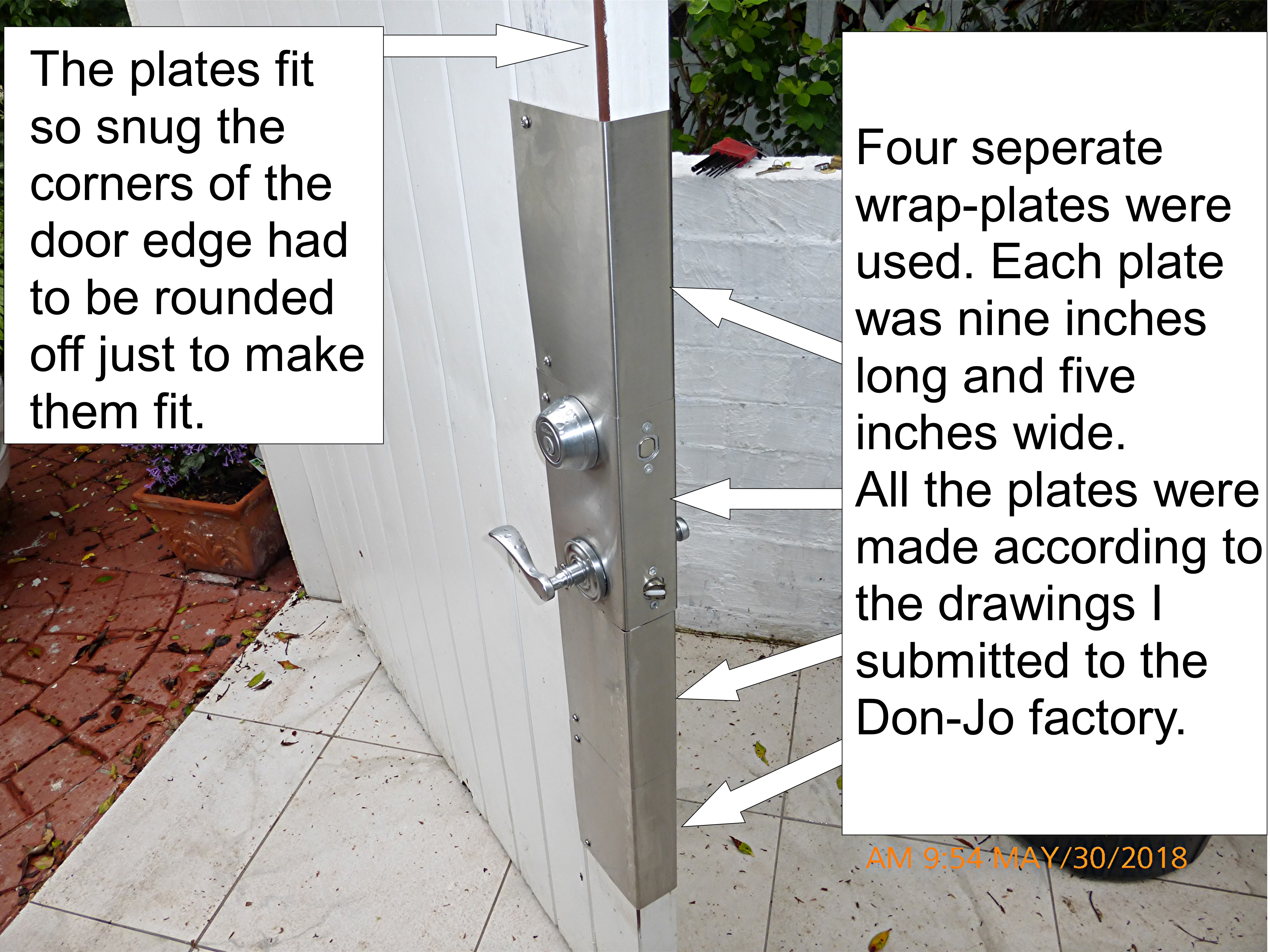

I offered a solution I thought would be cost effective, plus give the locking hardware a solid foundation to mount onto. I submitted drawings to the Don-Jo Manufacturing Company (Don-Jo) to have custom wrap-a-round plates made of stainless steel. The cost was outrageous and I advised the customer to consider replacing the whole gate. The customer decided to install the wrap-a-round plates for two reasons. First, he liked my work and did not want to go through the hassle of getting quotes and finding someone whose work he could trust. Second, the stainless steel plates would add years of maintenance free operation to the gates life.

I ordered the custom hardware and a new deadbolt. The deadbolt would need a special “extension kit” for installing into an extra-thick door. All the hardware arrived in about 5 weeks, which is normal for custom order hardware.

The edge of the gate was plugged with new wood (no photo) so the gate could be re-bored, placing the latch and deadbolt in the true center of the gate. In the “before” photos it is easy to see the latch and deadbolt are not centered.

The wrap-a-round plates could only be made for a 2 ¼ inch thick door. The gate was 2 5/16 inches thick. The plates were 1/16 of-an-inch to narrow. I used wood clamps to compress the door but still had too round-off the corners of the gate edge to get the plates fitting snug and square. The finished product reinforced the existing wood plus covered all the exposed cracks and attempts to re-bore and counter-bore holes for the deadbolt lock.

The gate frame had to be shaved down with a block plane and rabbit plane to compensate for the wrap-a-round plate thickness. The strike plates were anchored through the frame into the block wall using Tap-Con concrete screws. Later on the wrap-a-round plates were painted to blend-in with the gate.