Installing a Safe in a Wood Cabinet

By Jeff Gater, CML

Some time ago an executive secretary contacted me on behalf of her employer who wanted a small safe installed in a cabinet, but bolted into the concrete floor to prevent thieves from ripping out the safe and carrying it away.

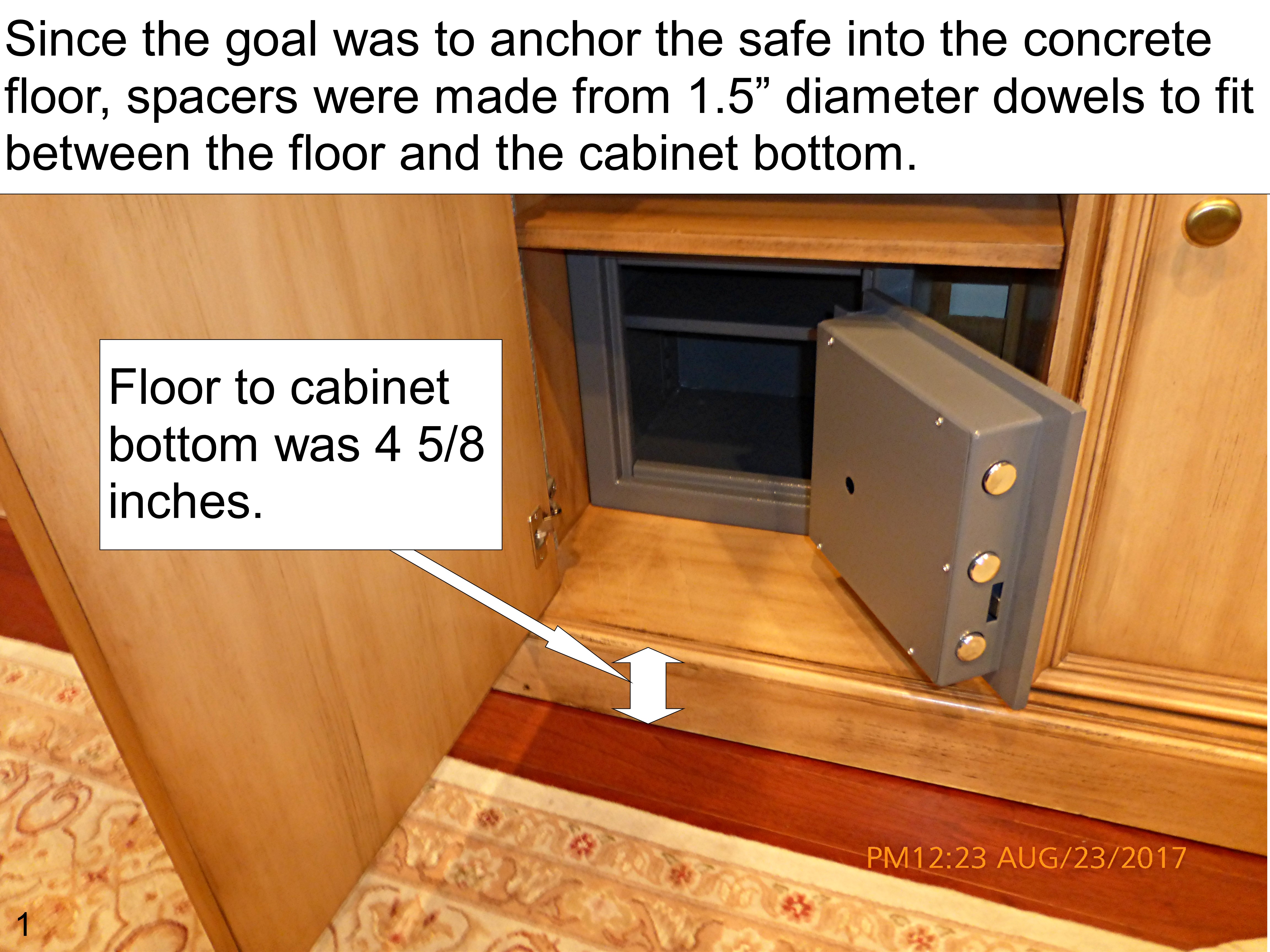

I stopped by to measure the cabinet. My plan was to pull the furniture away from the wall and measure the distance from the floor to the bottom of the cabinet where the safe would sit. The hollow space between the cabinet bottom and the floor would have to be filled in so the anchor bolts would not stress or crush the cabinet when the safe was bolted down.

When I arrived to measure, the cabinet was 16 feet long and 7 feet tall, there was no way to pull it away from the wall. I opened the cabinet door and measured from the floor to the cabinet bottom. My original plan was to fill the hollow space with blocks of wood or large dowels. Now the plan was to make the anchor bolt pass through the dowel and into the steel anchor. This would require boring a large hole in the cabinet bottom so the dowel could be installed from the top.

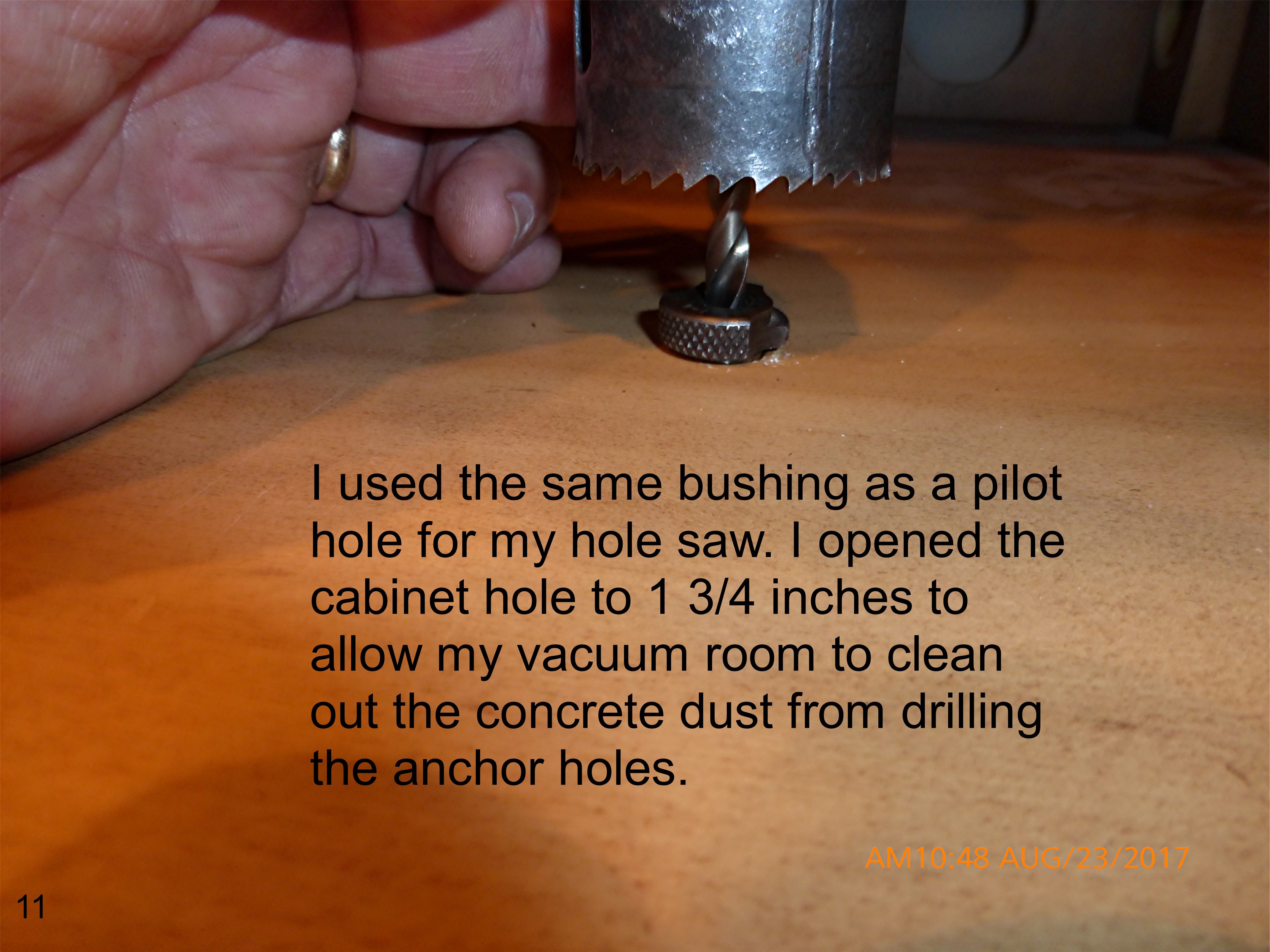

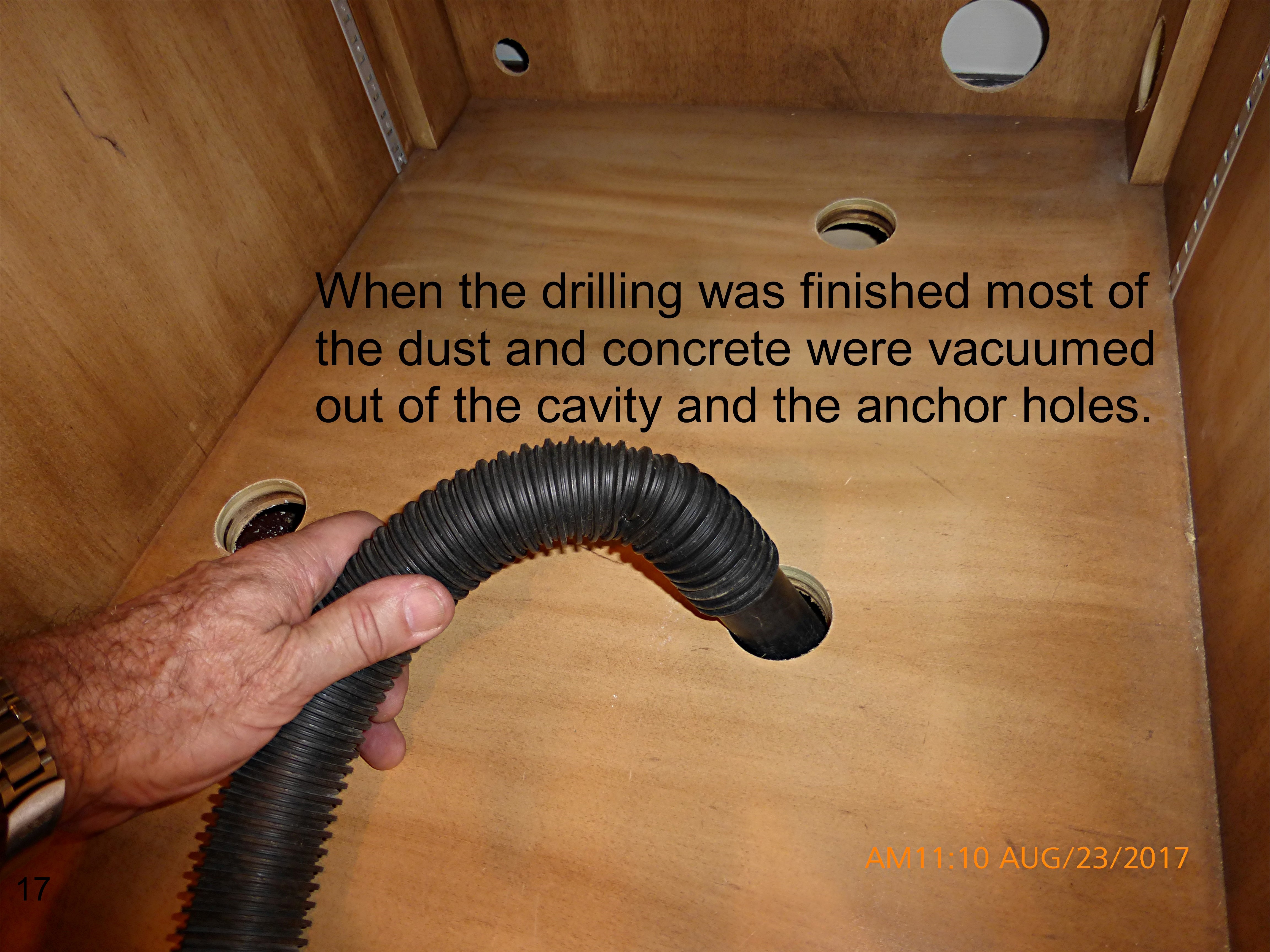

I chose a 1 ½ inch dowel which would allow me to cut a 1 ¾ inch hole through the cabinet bottom. Any larger and the holes would show on the sides of the safe. A smaller hole would make the job very difficult. The hole had to be large enough to fit a vacuum hose for removing the concrete dust when drilling for the drop anchors.

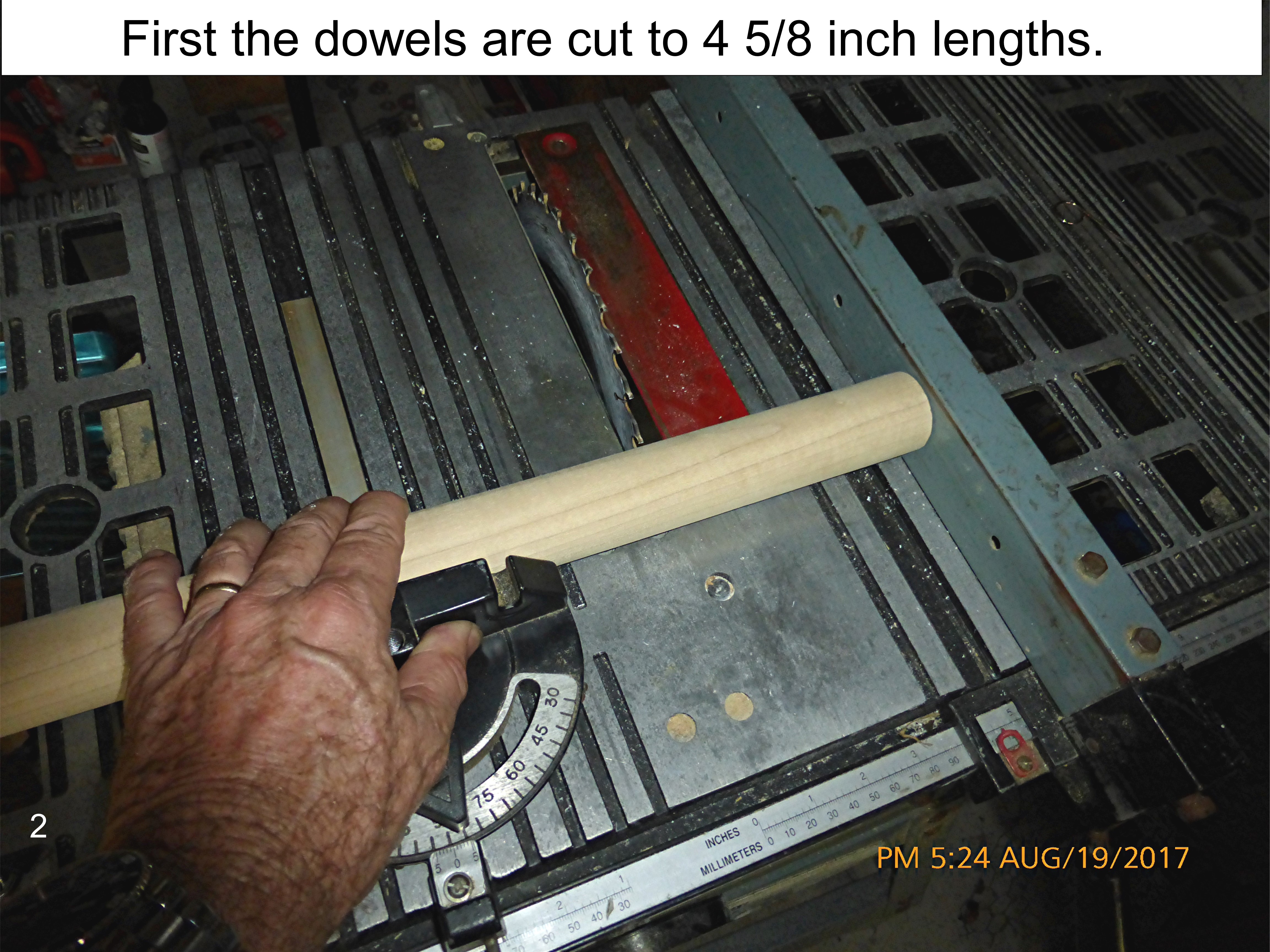

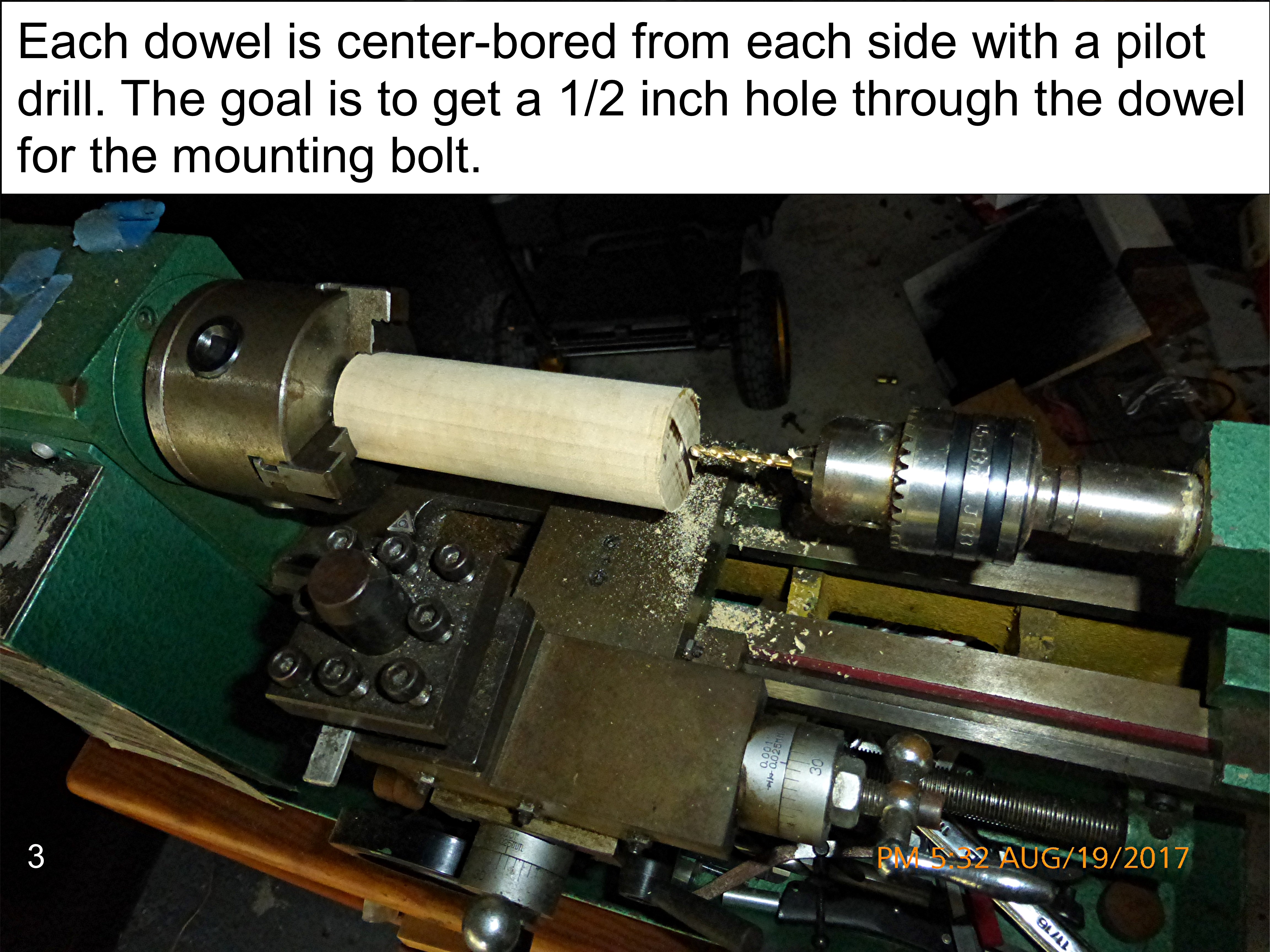

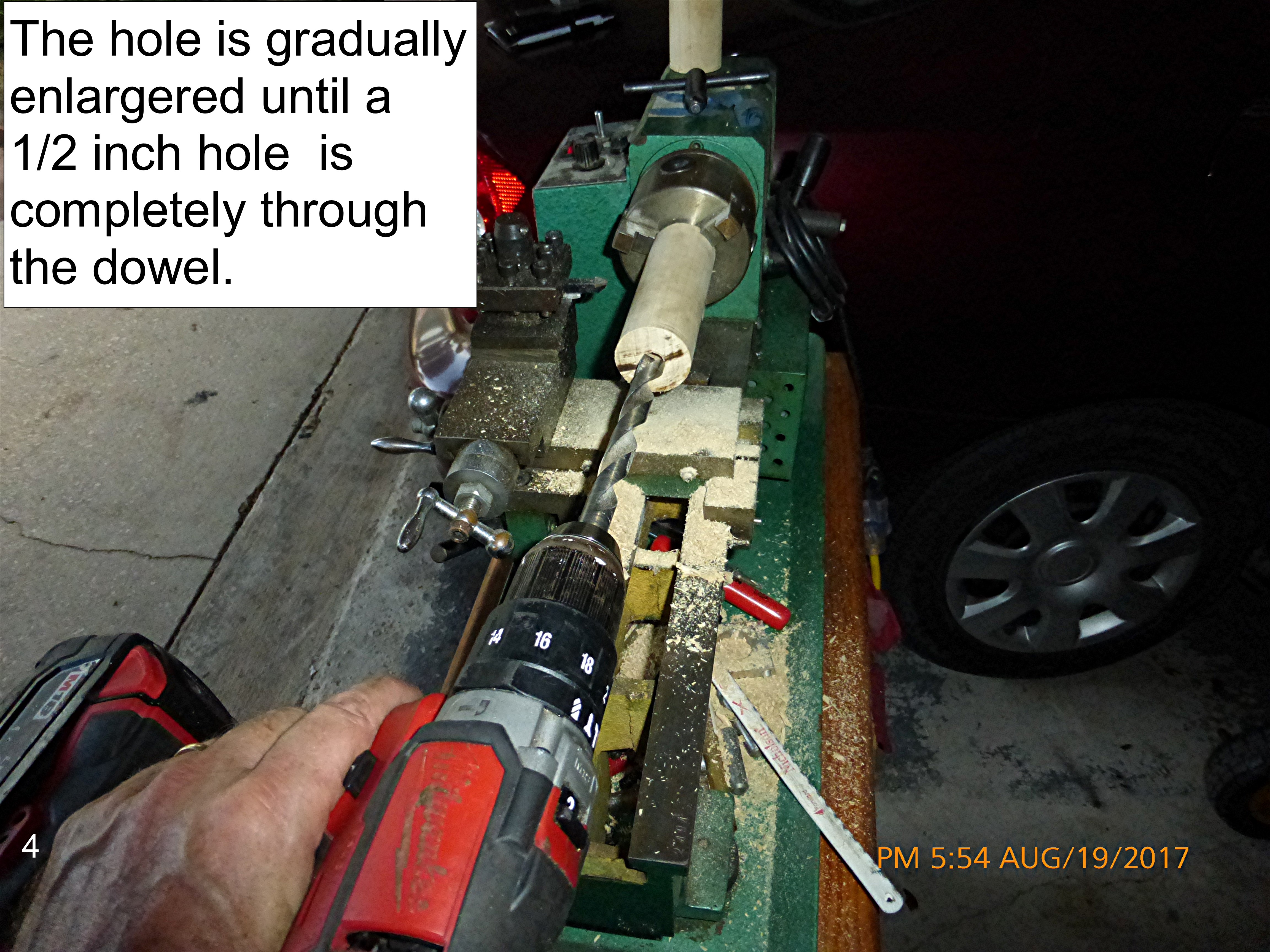

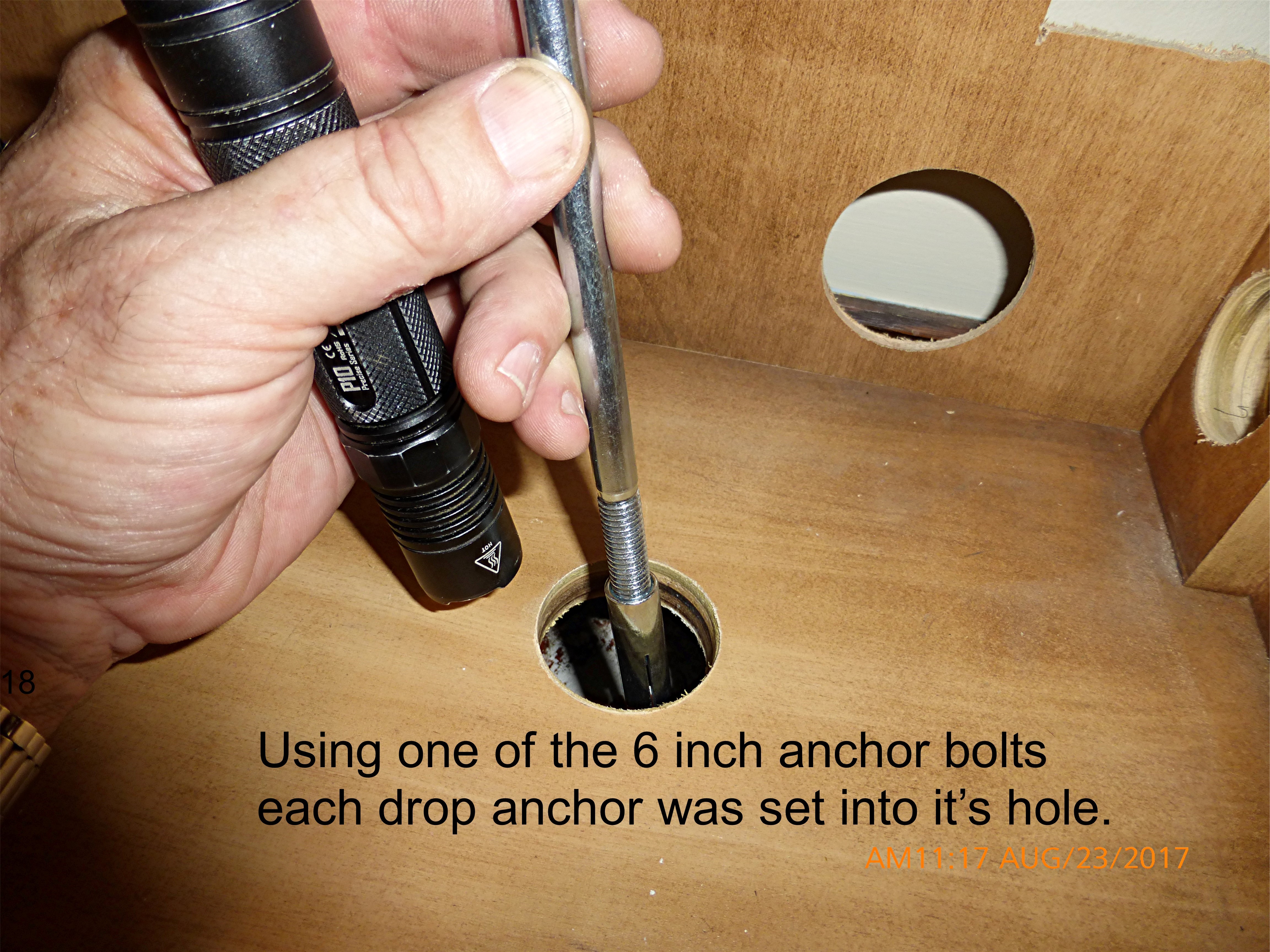

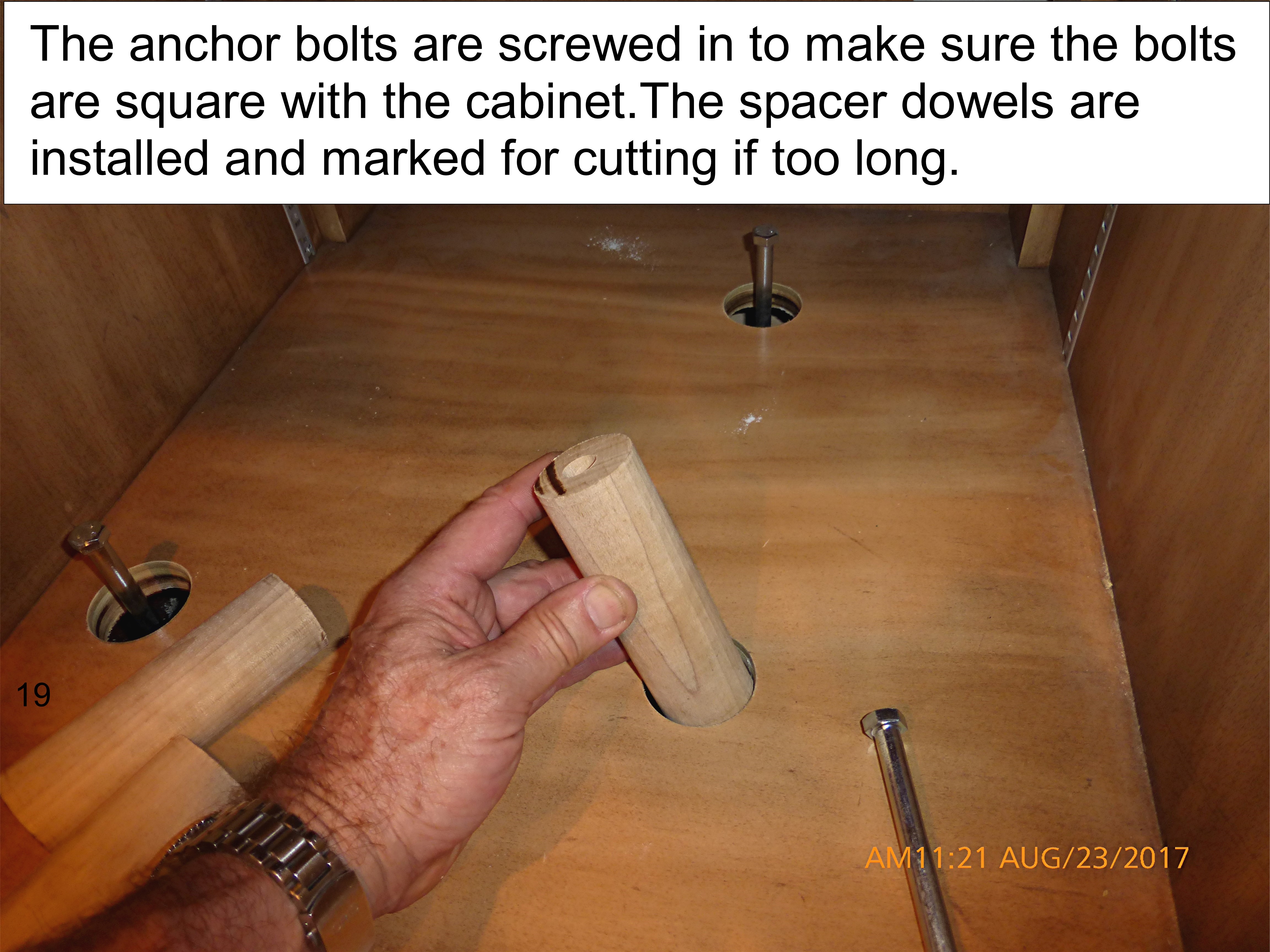

The dowels were cut to size on a table saw. Boring the ½ inch hole through the center of the dowel started by clamping the dowel in a metal lathe and boring a pilot hole from either side, gradually making the holes larger until the ½ inch hole was bored perfectly through the center of the dowel.

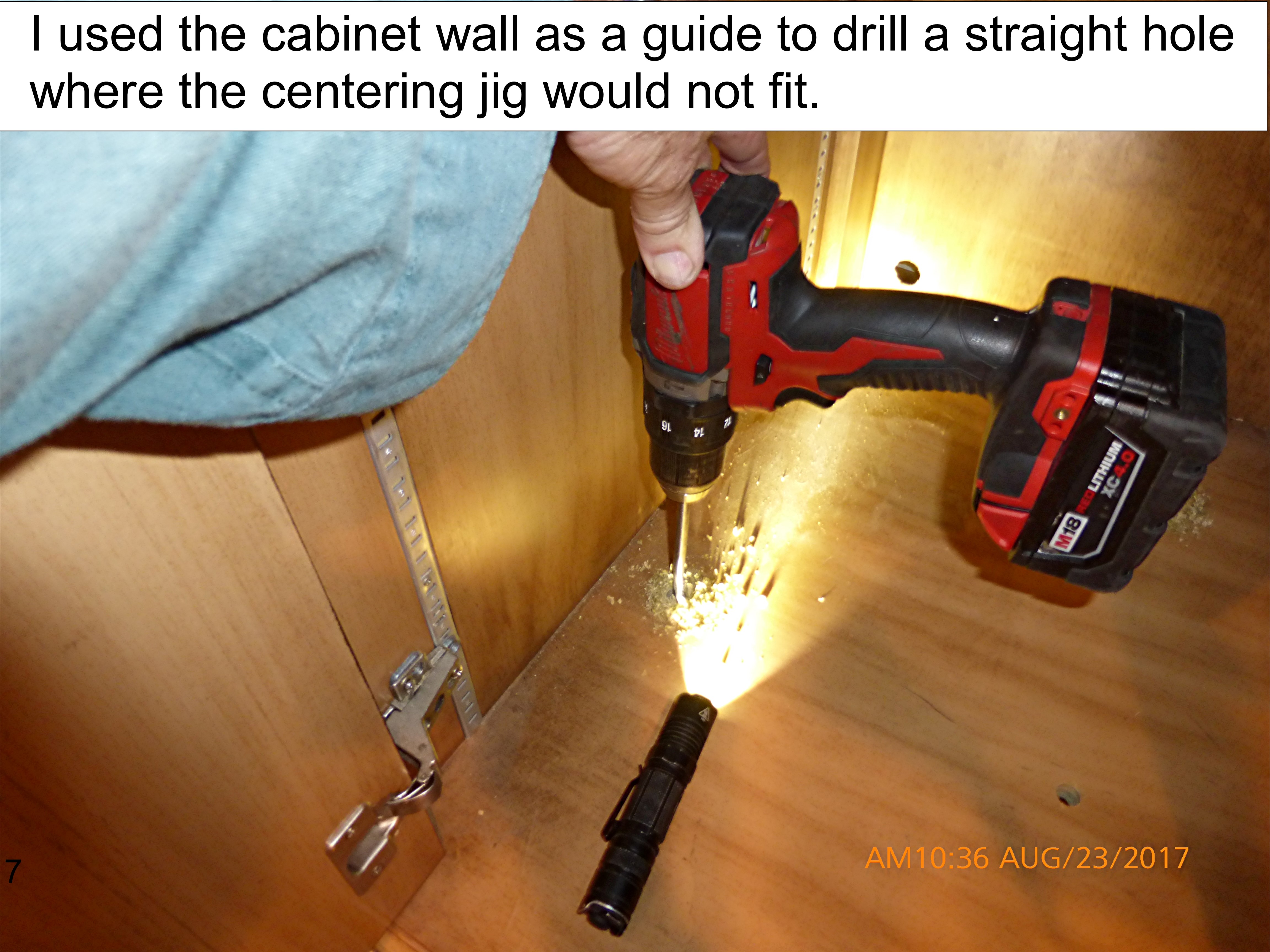

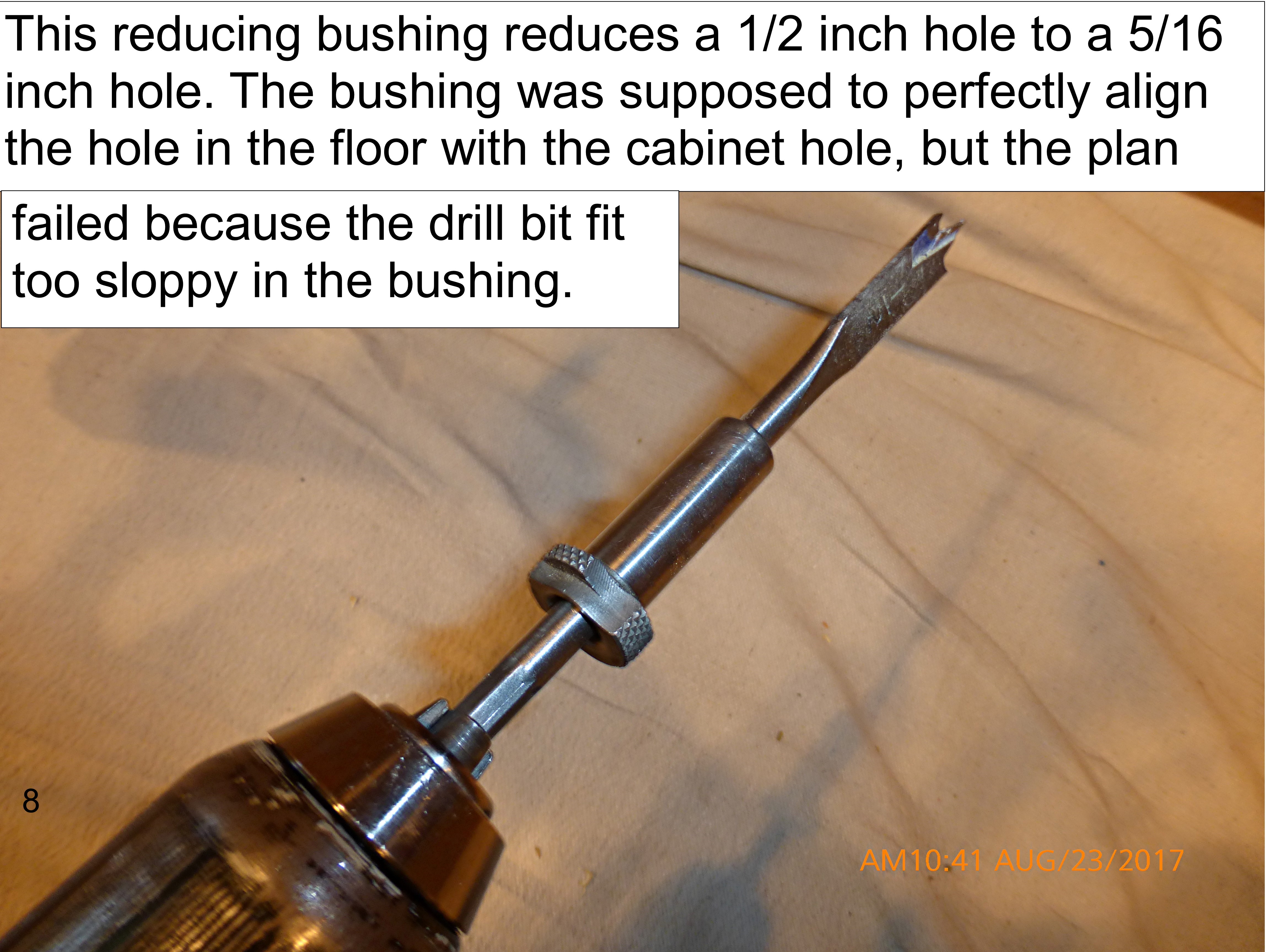

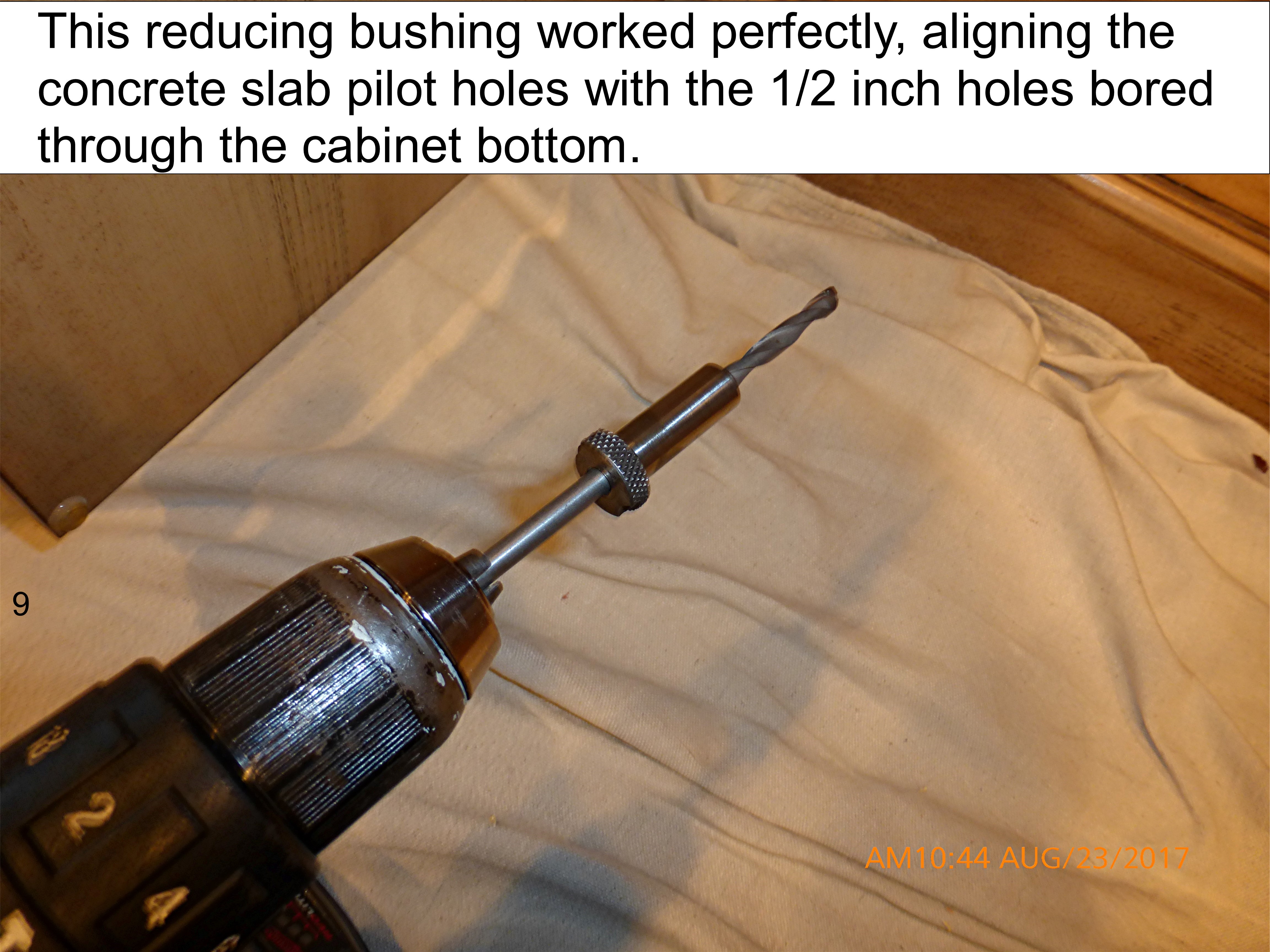

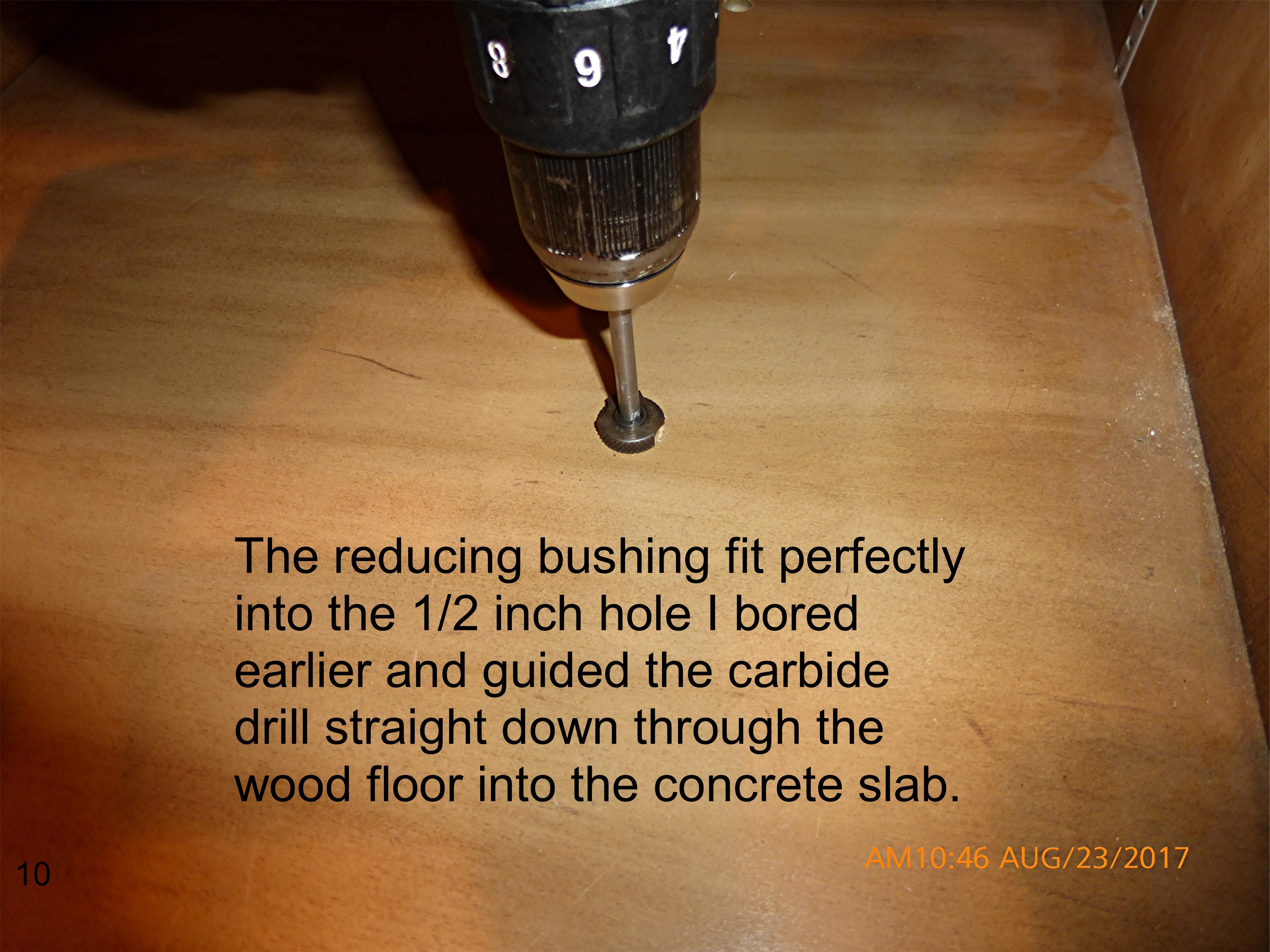

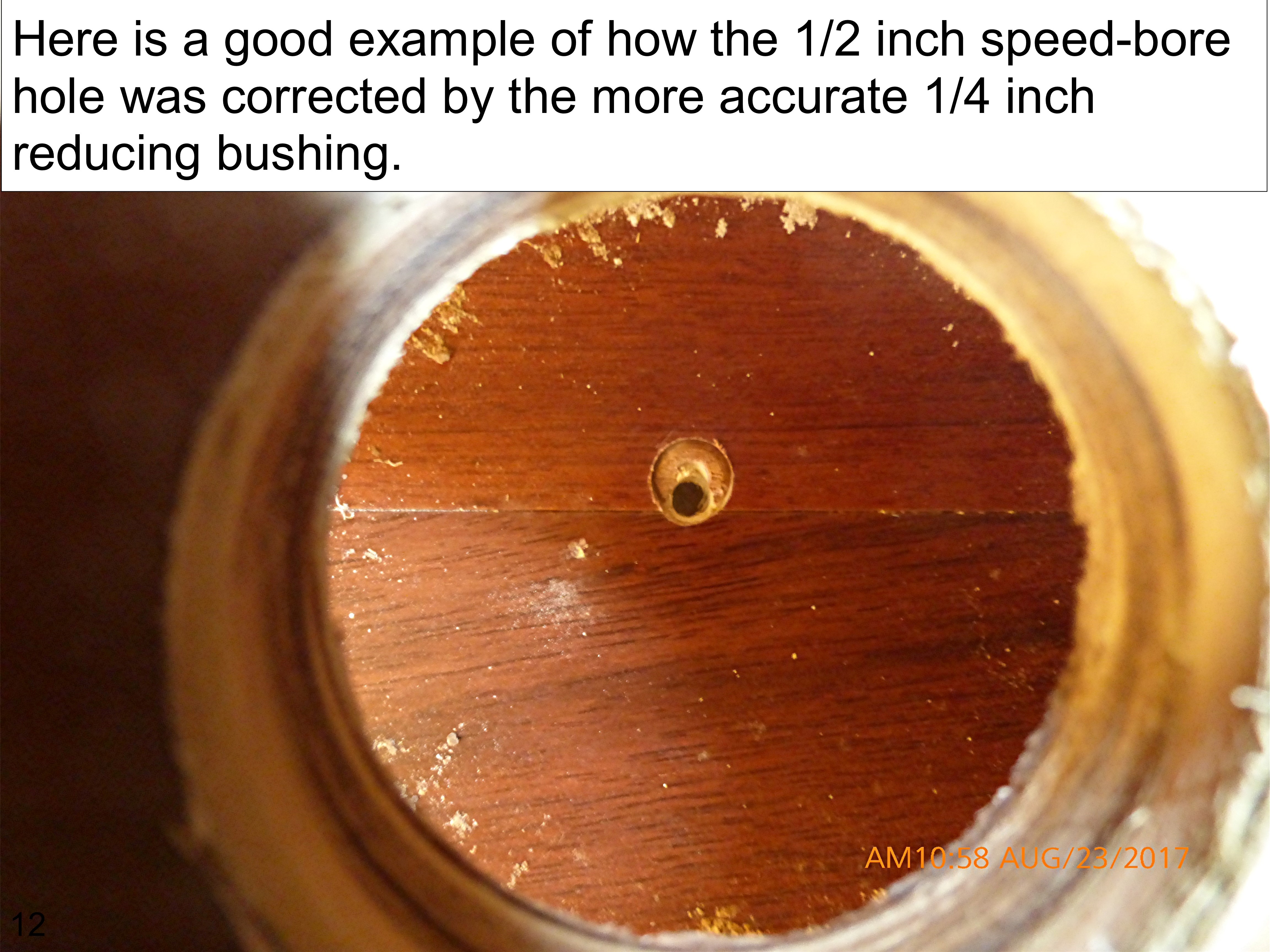

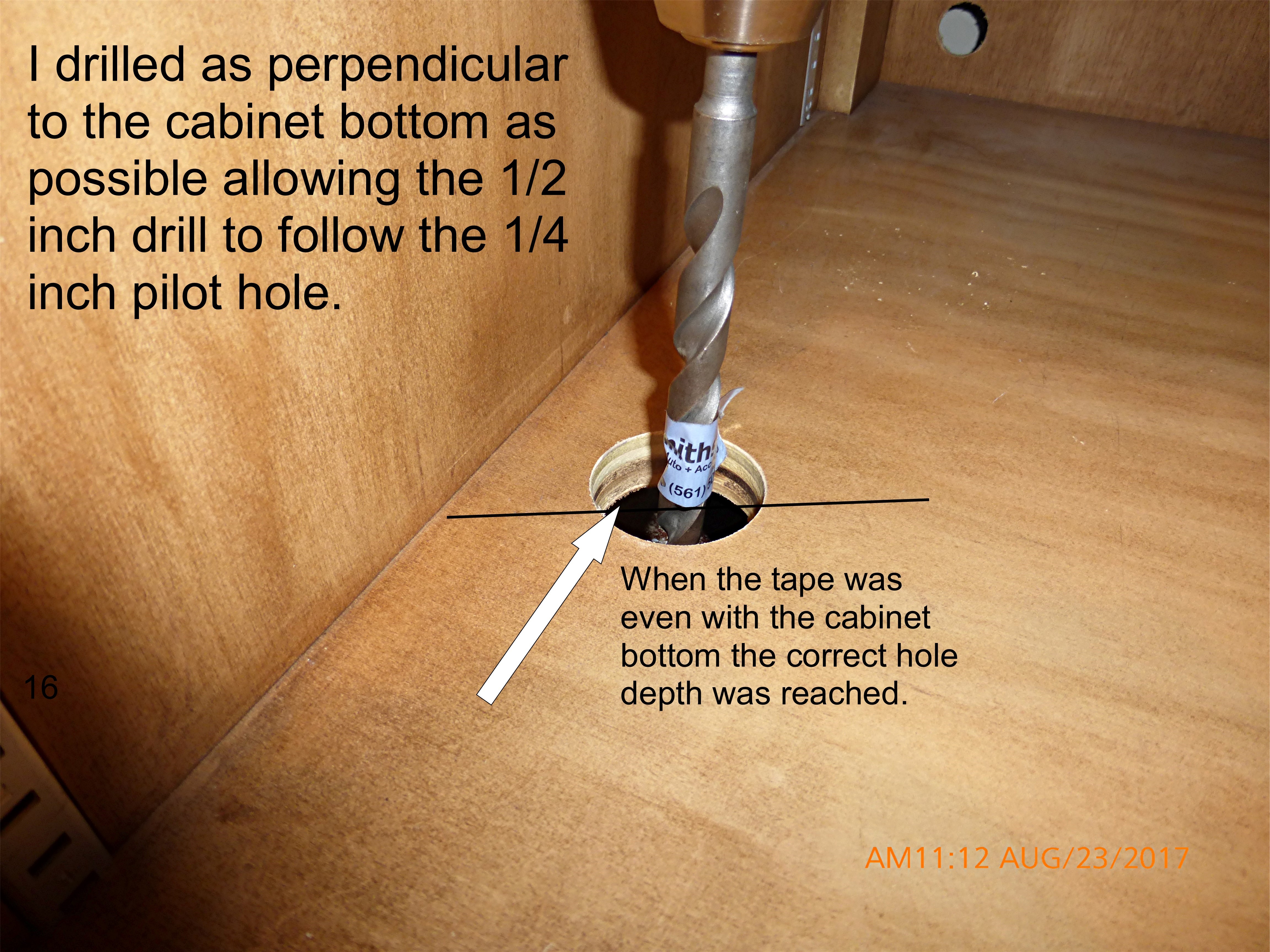

The greatest challenge was making a straight hole through the cabinet, the empty space between the cabinet and the floor, the wood floor and the concrete floor without the drill going off track. To accomplish this I used a reducing bushing from my lock installation jig. The bushing reduces a half inch hole in the jig to a quarter inch hole used to guide a quarter inch pilot drill through metal doors. I tried a 5/16 inch reducing bushing with a wood cutting speed-bore drill, but the drill fit sloppy which allowed the hole to wander.

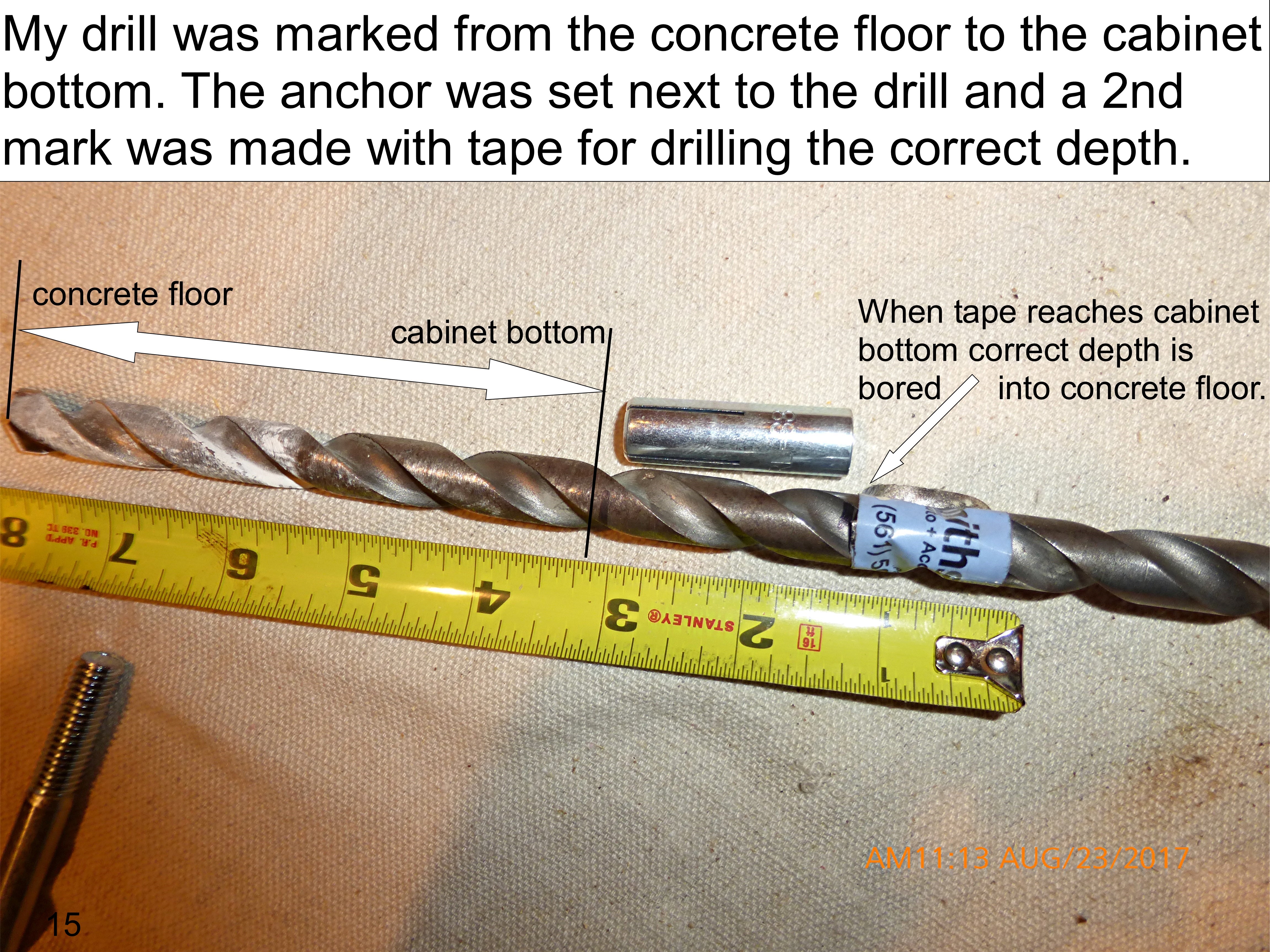

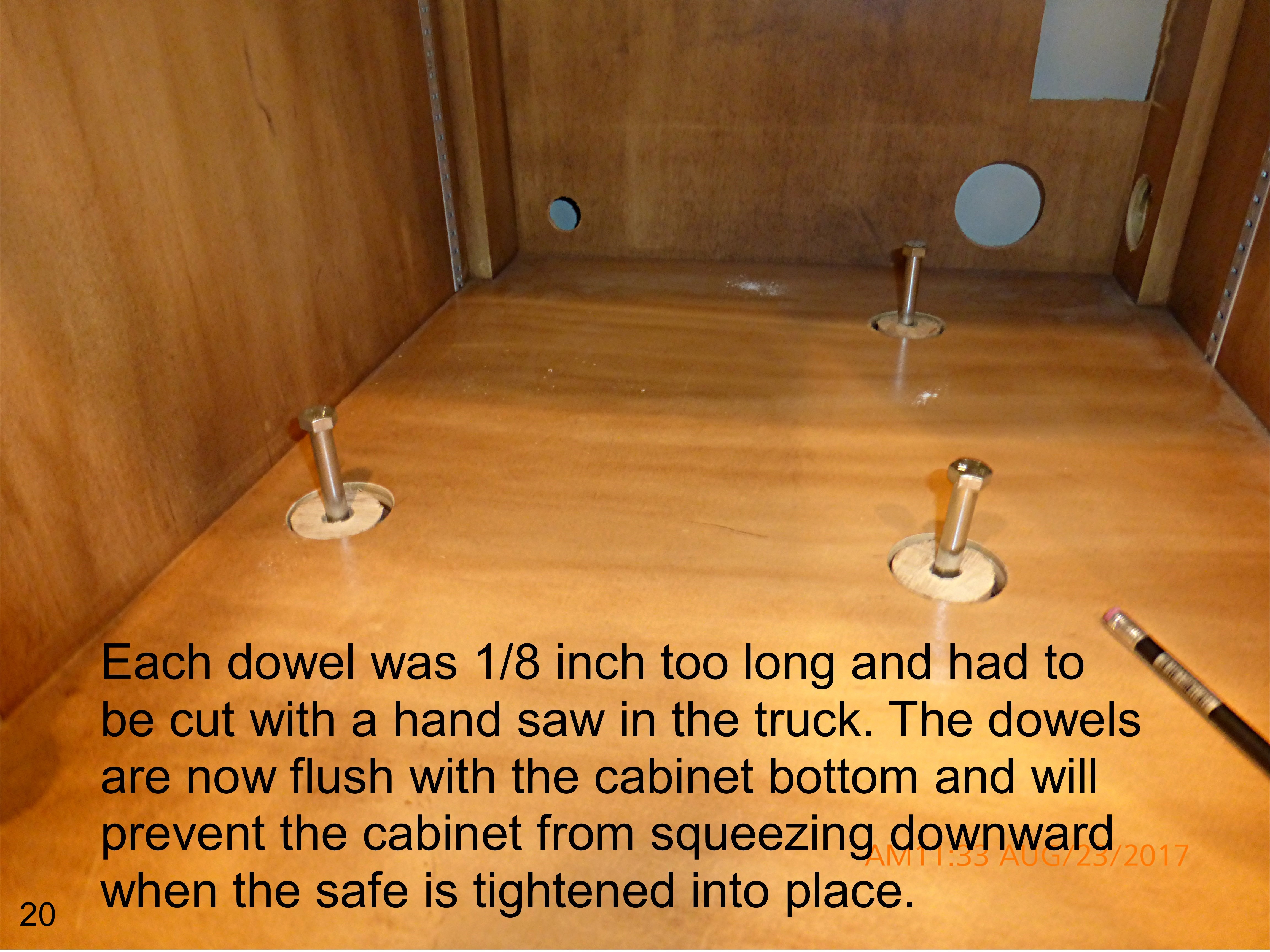

When the reducing bushing guided the carbide drill to a perfect transition from cabinet to floor, the same bushing was used to guide a 1 ¾ inch hole saw to open up the holes through the cabinet bottom. The 1 ¾ inch hole allowed room for a flash light to see all three holes for drilling, vacuuming and setting the steel anchors into the concrete floor. The dowels used for spacers were too long and cut to size using a vise and a hand saw in the back of the truck.

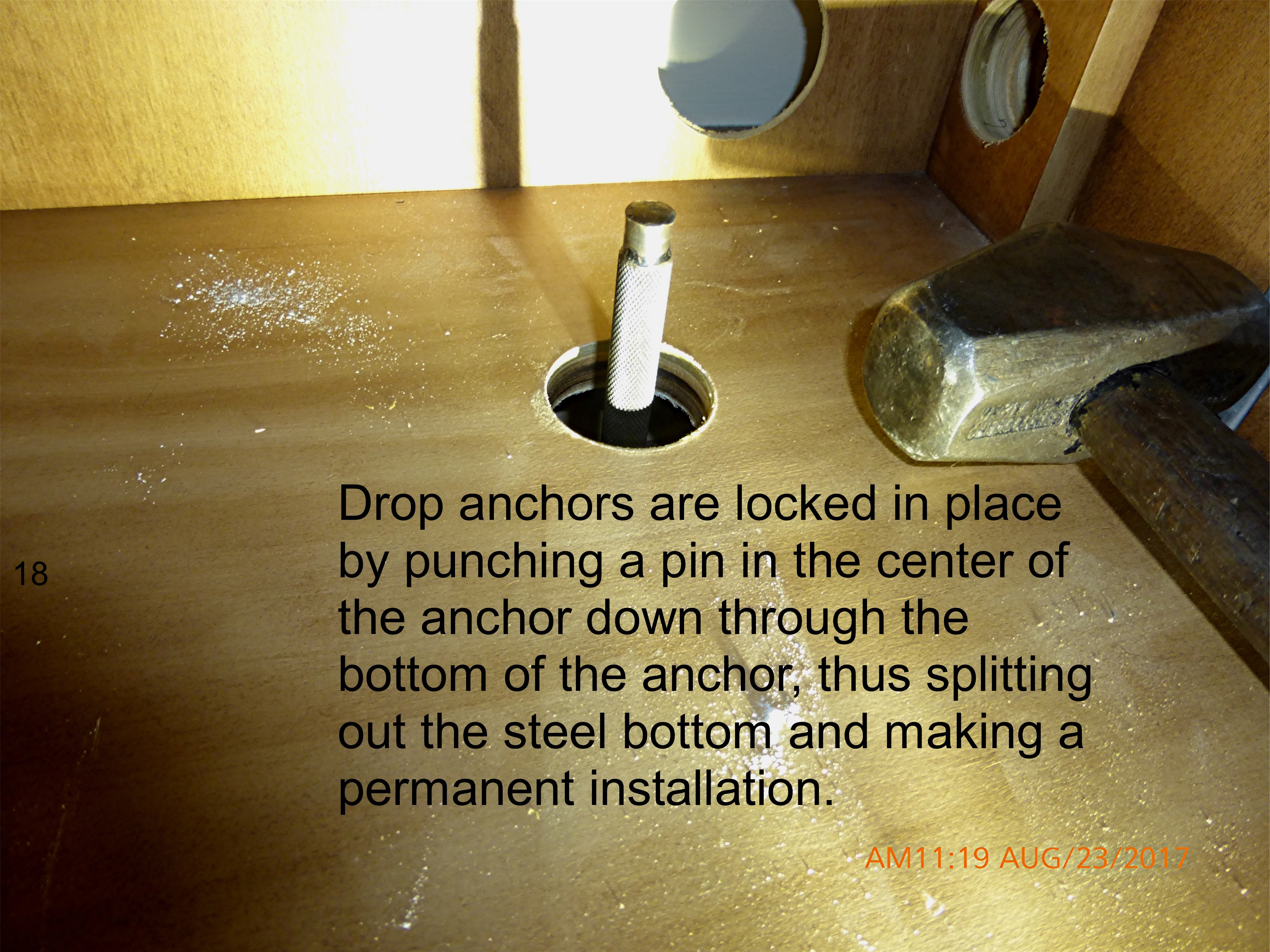

The anchor alignment was so perfect the anchor bolts threaded in perfectly and the safe was almost secure as being welded to a steel I-beam.