The last piece of legislation signed into law by President George H. W. Bush in 1990 was the American Disabilities Act. This law changed many building codes to compensate for access of public places to disabled Americans. Existing buildings were not grandfathered in, but the law did allow private entities to install lever-locks on an as needed basis. The two hospitals I service were not required to replace all the existing door knobs immediately, but as hardware wore out a door knob was to be replaced with a lever-lock.

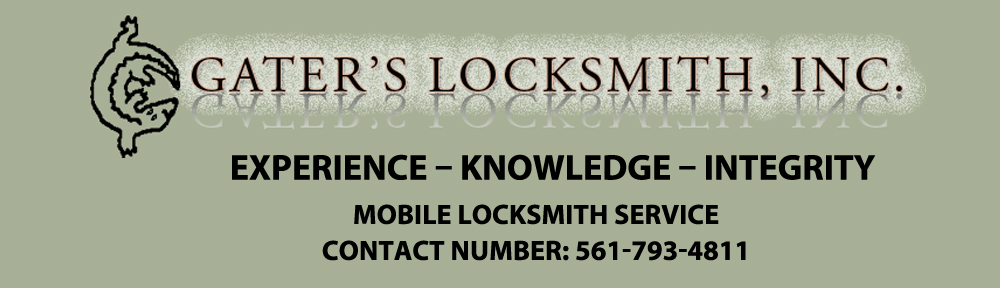

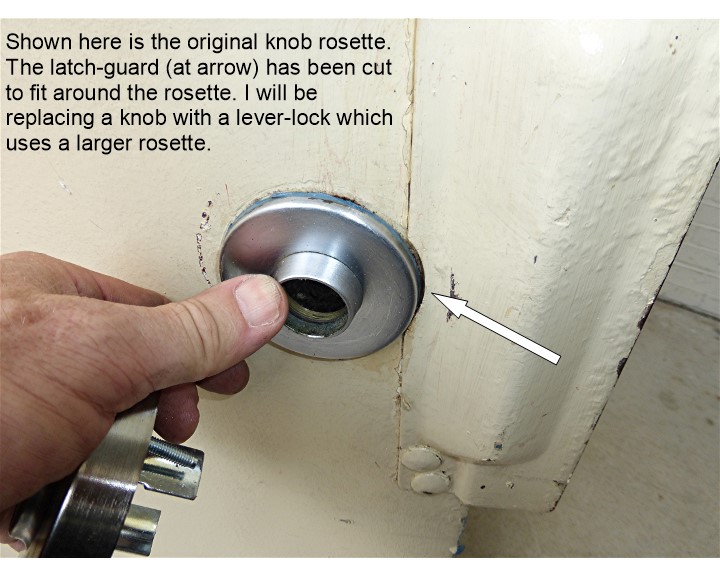

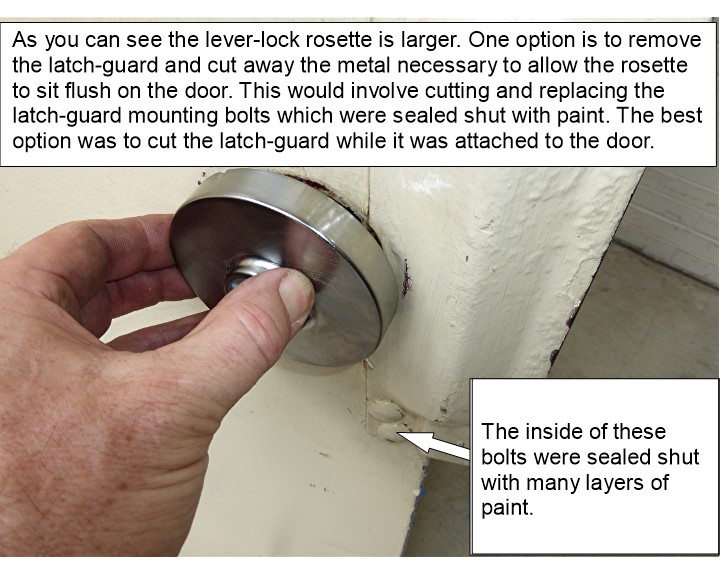

Recently I had to replace a door knob which was installed when a hospital was constructed back in 1982. The problem was a latch-guard was installed with the knob to prevent unauthorized access to someone with a pry tool or large screwdriver. The carriage bolts used to hold the latch-guard to the door were covered with many (possibly hundreds) layers of paint. The only way to remove the latch-guard from the door would be to cut the bolts off with a hack saw. The latch-guard was cut out to fit around the door knob. Lever-locks however have larger rosettes which house the lever return springs. The heavy springs used in these larger rosettes keep the lever in a horizontal position after many thousands of cycles. A typical Medication Room in a hospital could be opened as many as 80,000 times in 6 months. Grade 1 lever-locks are designed for this kind of heavy use.

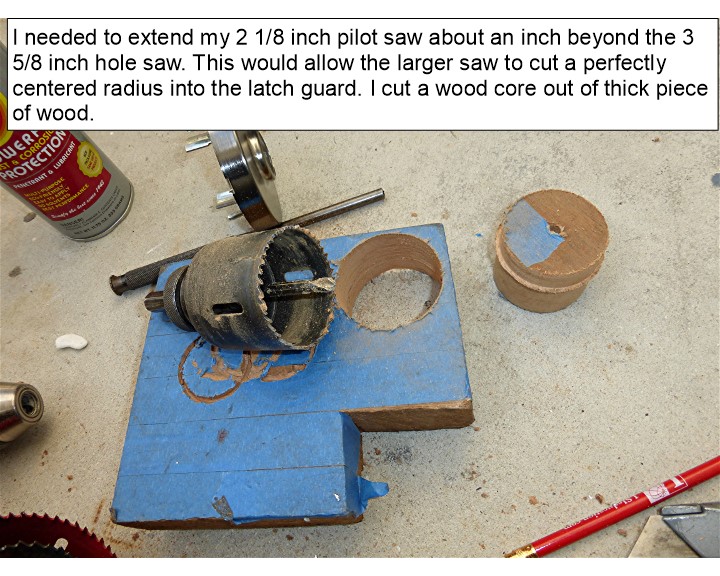

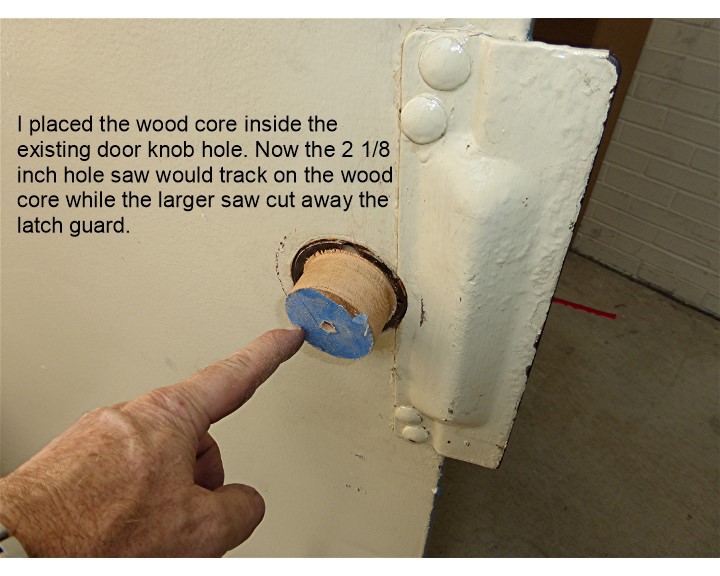

My problem at the time was fitting a lever-lock onto a door when the existing latch-guard would not allow it to fit flush up against the door. Since removing the guard would create a royal mess I decided to cut away a piece of the guard to make room for the larger rosette. The following photos will explain how I used a simple technique to solve a complicated problem.